SDY630/400 BUTT FUSION UMACHINE ISIKHOKELO SOKUSEBENZA

Inkcazo ekhethekileyo

Sincoma ukufunda yonke isicatshulwa ngononophelo kakhulu ukuze uqinisekise ukhuseleko lomsebenzisi kunye nezixhobo ngaphambi kokuba uqale ukusebenzisa umatshini. Le ncwadana yokusebenza kufuneka igcinwe ngononophelo ukulungiselela ikamva.

3.1 Esi sixhobo asihambelani nokungachazi ukuwelda kwemibhobho yezinto; kungenjalo inokonakalisa okanye yenzeke ngengozi.

3.2 Ungawusebenzisi umatshini kwindawo yogqabhuko-dubulo.

3.3 Lo matshini mawusetyenziswe ngumsebenzi oyingcali.

3.4 Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

3.5 Amandla egalelo yi-380V±10%, i-50Hz. Ukuba kusetyenziswa umgca wokufaka owandisiweyo, umgca kufuneka ube necandelo elikhokelayo elaneleyo.

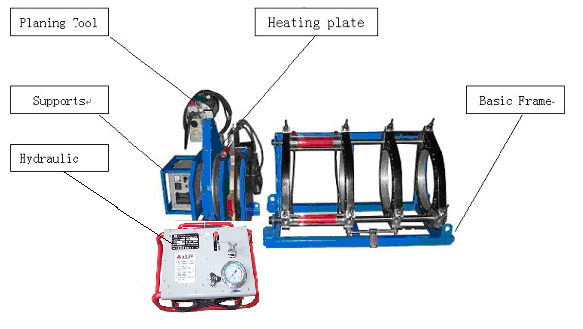

Inkcazo yamacandelo

Umatshini wenziwa kwisakhelo esisisiseko, iyunithi ye-hydraulic, ipleyiti yokufudumeza, isixhobo sokucwangcisa, inkxaso yesixhobo sokucwangcisa kunye nebhokisi yombane.

3.1 ulungelelwaniso lomatshini

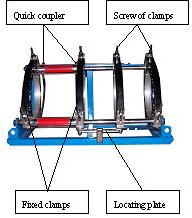

3.2 Isakhelo esisisiseko

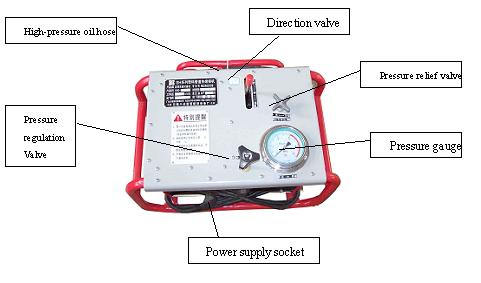

3.3 iiyunithi zehydraulic

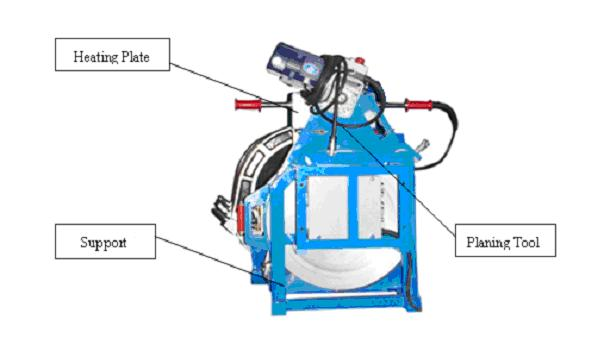

3.4 Isixhobo sokucwangcisa kunye nepleyiti yokufudumeza

Umyalelo wokusetyenziswa

4.1 Zonke iindawo zezixhobo kufuneka zibekwe kwinqwelomoya ezinzileyo neyomileyo ukuze isebenze.

4.2 Qinisekisa amandla ngokuhambelana nomatshini wokudibanisa i-butt eceliwe, umatshini ukwimeko efanelekileyo, umgca wombane awuzange uphuke, zonke izixhobo ziqhelekileyo, ii-blades zesixhobo sokucwangcisa zibukhali, zonke iindawo eziyimfuneko kunye nezixhobo zigqityiwe.

4.3 Uqhagamshelo lwe-hydraulic kunye nombane

4.3.1 qhagamshela isakhelo esisisiseko kunye neyunithi yehydraulic nge-coupler ekhawulezayo.

4.3.2 qhagamshela umgca weplate yokufudumeza kwibhokisi yombane kwisakhelo esisisiseko.

4.3.3 qhagamshela umgca wepleyiti yokufudumeza kwipleyiti yokufudumeza.

4.3.4 Fakela izinto ezifakelweyo ngokwedayamitha engaphandle yombhobho / ukufakwa kwisakhelo esisisiseko.

4.4 Inkqubo yokuwelda

4.4.1 Qwalasela i-diameter kunye nobukhulu bodonga okanye i-SDR yemibhobho/izifakelo eziza ku-welding zilungile. Umphezulu wayo kufuneka utshekishwe ngaphambi kokuba uqalise ukutshiza, ukuba umkrwelo udlula i-10% yobukhulu bodonga, kufuneka usikwe ngokuyinxenye ukusebenzisa.

4.4.2 Coca umphezulu wangaphakathi nangaphandle wombhobho odityanisiweyo.

4.4.3 Beka imibhobho/izifakelo kwizifakelo zefreyimu, ubude bemibhobho/izifakelo eziphela zizakudityaniswa ziphuma kwindawo efakwe kuyo mhlawumbi ziyafana (zimfutshane kangangoko kunokwenzeka). Esinye isiphelo sombhobho kufuneka sixhaswe ngama-roller ukunciphisa ukukhuhlana. Emva koko ujije isikrufu seziqhoboshi ukuze ubambe imibhobho/ukufaka.

5.4.4 Beka isixhobo sokucwangcisa kwisakhelo phakathi kwemibhobho/izifakelo ekupheleni kwaye uvule, vala imibhobho/iziphelo zofakelo ngokusebenzisa ivalve yendlela yokusebenza yeyunithi yehydraulic de kubekho ukuchetywa okuqhubekayo kubonakala kuzo zombini iziphelo.(uxinzelelo lokucheba ngaphantsi kwe-2.0 Mpa). Beka ibha yevalve yolwalathiso kwindawo ephakathi kwaye ugcine imizuzwana embalwa, emva koko uvule isakhelo, cima isixhobo sokucwangcisa kwaye usisuse ngaphandle kwesakhelo. Ubukhulu be-shavings kufuneka bube yi-0.2 ~ 0.5 mm kwaye bunokulungelelaniswa ngokuhlengahlengisa ukuphakama kwezixhobo zokucwangcisa izixhobo.

4.4.5 Vala imibhobho/iziphelo zokulinganisa kwaye uhlole ukungahambi kakuhle kwazo. Ubuninzi. Ukungahambi kakuhle akufanele kudlule i-10% yobunzima bodonga, kunokuphuculwa ngokulungelelanisa ukulungelelaniswa kombhobho kunye nokukhulula okanye ukuqinisa i-screws of clamps. Umsantsa phakathi kweziphelo zemibhobho emibini akufanele udlule i-10% yobukhulu bodonga, okanye kufuneka unqunywe kwakhona.

4.4.6 Sula uthuli kwaye uhlale kwipleyiti yokufudumeza (Musa ukukrwela i-PTFE umaleko kumphezulu wepleyiti yokufudumeza).

4.4.7 Beka ipleyiti yokufudumeza kwifreyimu phakathi kweziphelo zombhobho emva kokufika kobushushu obufunekayo. Phakamisa uxinzelelo ukuya kwimfuno yalo de i-bead ifikelele kubude obuchanekileyo.

4.4.8 Ukunciphisa uxinzelelo kwixabiso elaneleyo ukugcina iziphelo zombini zemibhobho / izixhobo ezidibanisa nepleyiti yokufudumeza ixesha elifunekayo.

4.4.9 Xa ixesha lifikile, vula ifreyimu kwaye ukhuphe ipleyiti yokufudumeza, vala iziphelo ezimbini zokunyibilika ngokukhawuleza.

4.4.10 Yandisa uxinzelelo ukuya kuxinzelelo lwe-welding kwaye ugcine ijoyinti kwixesha lokupholisa. Ukukhulula uxinzelelo, khulula i-screw of clamps kwaye ukhuphe umbhobho odibeneyo.

Isixhobo sexesha

Ukuba enye iparameter itshintshiwe, njenge-diameter engaphandle, i-SDR okanye izinto zombhobho, i-soak ngexesha lokufudumeza kunye nexesha lokupholisa kufuneka libuyiselwe ngokwemigangatho ye-welding.

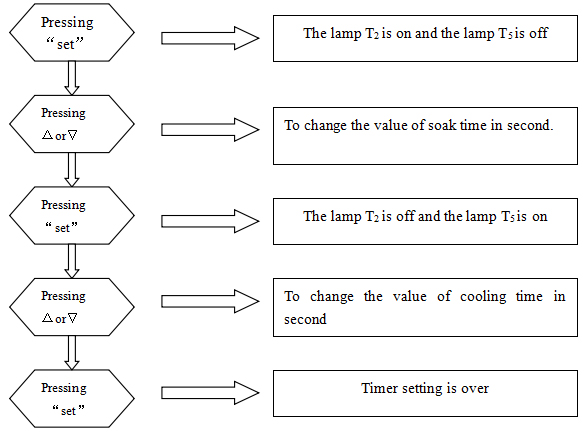

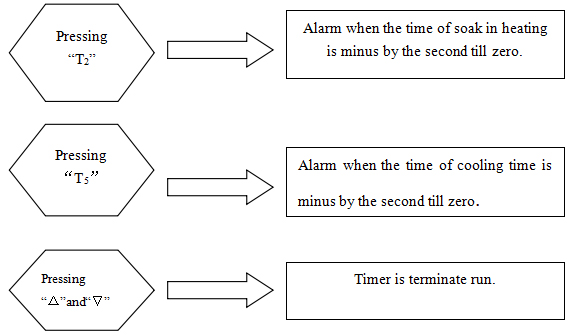

6.1 Ukusetha ixesha

6.2 Umyalelo wokusetyenziswa

Welding umgangatho kunye khangela

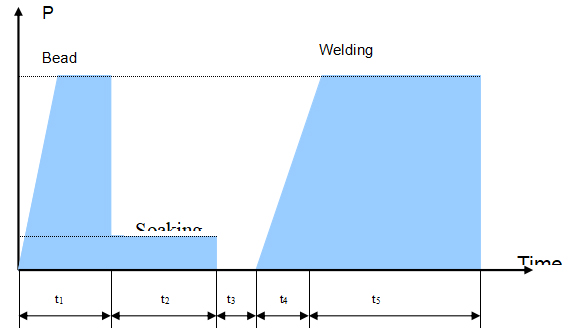

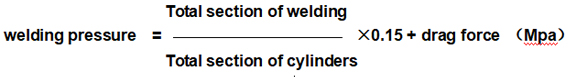

7.1 Ngenxa yemigangatho ye-welding eyahlukeneyo kunye nezinto ze-PE, ixesha kunye noxinzelelo lwesigaba senkqubo ye-butt fusion iyahluka. Iphakamisa ukuba imibhobho kufuneka ibonise imilinganiselo ye-welding yangempela kunye nokuveliswa kwezixhobo.

7.2 Umgangatho wolwaziDVS2207-1-1995

| Ubunzima bodonga (mm) | Ubude bentsimbi (mm) | Uxinzelelo lwe-bead (Mpa) | Ixesha lokuhamba t2(Umzuzwana) | Uxinzelelo lokuntywila (Mpa) | Ukutshintsha kwexesha t3(Umzuzwana) | Ixesha lokunyuka t4(Umzuzwana) | Uxinzelelo lweWelding (Mpa) | Ixesha lokupholisa t5(min) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45 ~ 70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7 ~12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 ~8 | 6 ~8 | 0.15±0.01 | 10~16 |

| 12 ~ 19 | 2.0 | 0.15 | 120 ~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10~12 | 11 ~ 14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12 - 16 | 14 ~ 19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16 ~ 20 | 19 ~ 25 | 0.15±0.01 | 45 ~ 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~700 | ≤0.02 | 20 ~ 25 | 25 ~ 35 | 0.15±0.01 | 60 ~ 80 |

Phawula:

Amabinzana:

Intengiso yenkqubo yokhuseleko

Kucetyiswa ngamandla ukuba ufunde kwaye ulandele ngononophelo le mithetho ilandelayo ngokukhuselekileyo phambi kokuba usebenze umatshini.

8.1 Abasebenzi bezakhono kufuneka baqeqeshe phambi kokuba bawusebenzise kwaye bawusebenzise umatshini.

8.2 Umatshini kufuneka uhlolisise kwaye ulungise kwaye usebenzise iminyaka emibini edlulileyo kwicala elikhuselekileyo.

8.3 Amandla: Iplagi yonikezelo lombane ibonelelwa ngomgaqo wokhuseleko kubasebenzi bezakhono kunye nokhuseleko lomatshini.

Indawo ekhuselekileyo kufuneka ibe negama okanye umfanekiso ukuze ichonge.

Qhagamshelana nomatshini kunye namandla: Amandla egalelo yi-380±20V ye-50Hz. Ukuba kusetyenziswa umgca wokufaka owandisiweyo, umgca kufuneka ube necandelo elikhokelayo elaneleyo.

I-Grounding: Kufuneka ibe nomqondiso wokudlulisa umgca kwindawo yokwakha, ukuchasana kunye ne-grounding is suit of protection setting kunye nokuqinisekisa ukuba ungadluli i-voltage ye-25 kunye nokuseta okanye ukuvavanywa ngumbane.

Ukugcinwa kombane: Umatshini kufuneka ube ngokuchanekileyo usebenzisa ugcino ukuqinisekisa ukhuseleko.

Qhagamshelana nomatshini kufuneka thethwano umgaqo osebenzayo.

※ Gwema naluphi na uhlobo lwengozi ebangelwa ngumbane.

※ Kuphephe ukunqunyulwa unikezelo lwamandla ngokutsala

※ Kuphephe ukuhamba, tsala kwaye ubeke umatshini ngentambo yentambo.

※ Gwema i-edge kwaye ulinganise kwi-cable-line, ubushushu be-cable-line akufanele budlule i-70℃.

※ Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

※ Indawo yokusebenza kufuneka icoceke.

※ Umatshini kufuneka uhlolwe kwaye ulungise ixesha lexesha.

※ Ngamaxesha ngamaxesha-umgca wentambo ye-insulation kufuneka ihlolisise kwaye icinezelwe ngokukodwa

※ Kuyingozi kakhulu ukusebenzisa umatshini xa kukho imvula okanye kwiimeko zengqolowa.

※ I-Residual current esebenzayo i-circuit breaker kufuneka ilungiswe ngenyanga.

※ Umntu osebenza ngoMbane kufuneka avavanye umgangatho wobume.

※ Xa uhlanjululwa ngomatshini ngononophelo, musa ukugubungela umatshini okhuselweyo okanye usebenzise i-benzine, ukukhulelwa kunye nokunye.

※ Umatshini kufuneka ugcinwe kwi-deiccation yemeko.

※ Zonke iiplagi kufuneka zicinywe kubonelelo lombane.

※ Ukusetyenziswa koomatshini abadlulileyo, umatshini kufuneka ugcine kwiimeko ezifanelekileyo zokusebenza.

Kucetyiswa ukuba ufunde kwaye ulandele ngokucophelela imithetho ekhuselekileyo ngaphambi kokuba usebenze umatshini.

Ingozi yokuqalisa: ngaphambi kokuba umatshini usebenze, iplagi yokubonelela ngombane inikezelwa ngokukhuselekileyo.

Imibhobho ebekwe kumatshini:

Beka imibhobho kwii-clamps kwaye uzibophe, umgama wesiphelo sepayipi ezimbini kufuneka ufake isixhobo sokucwangcisa kunye nokuqinisekisa ukusebenza, ugweme naluphi na uhlobo lwengozi olubangelwa ngumbane kunye nokusebenza.

Ukusebenza kwemeko:

Indawo yokusebenza kufuneka icoceke, yome kwaye ikhanyiswe ngokufanelekileyo.

Kuyingozi kakhulu ukusebenzisa umatshini xa kunemvula okanye kwiimeko zengqolowa okanye kufutshane nolwelo olunokutsha.

Qaphela ukuba bonke abantu abajikeleze umatshini bakumgama wokhuseleko.

Iimpahla:

Gcina ukhathalelo oluphezulu ngelixa usebenzisa umatshini ngenxa yobushushu obuphezulu obubandakanyekayo kwipleyiti yokufudumeza ihlala ingaphezulu kwe-200 ℃, kucetyiswa ngamandla ukuba usebenzise iiglavu ezifanelekileyo. Ziphephe iimpahla ezinde kwaye uphephe izacholo, iintsimbi zomqala ezinokubotshelelwa kumatshini.

Qaphela ingozi kwaye uthintele iingozi

Umatshini wokudibanisa iimpundu:

Ukusetyenziswa komatshini kufuneka kuqhutywe ngobuchule.

※ Isitya sokufudumeza

Ipleyiti yokufudumeza ngenxa yobushushu obuphezulu ngaphezu kwe-270 ℃, kucetyiswa ukuba uthathe imilinganiselo:

---sebenzisa iiglavu zobushushu obuphezulu

---emva kombhobho wokudityaniswa kwempundu ngombhobho, ipleyiti yokufudumeza kufuneka ifakwe.

---igqityiwe ipleyiti yokufudumeza kufuneka ibekwe kwibhokisi.

---ivumelekile ukuba ingachukumisi kwipleyiti yokufudumeza.

※ Isixhobo sokucwangcisa

---Ngaphambi kokusebenza kweScraping, imibhobho kunye nokuphepha komhlaba ukungcolisa imibhobho ejongene nayo iphela.

--- sigqityiwe isixhobo sokucwangcisa kufuneka sibekwe kwiNkxaso yesixhobo sokucwangcisa kunye nepleyiti yokufudumeza

※ Isakhelo esisisiseko

---iqale kwangethuba ukuba isakhelo esisisiseko ekudityanisweni okukhankanywe ngasentla Kulungele zonke iintlobo zombhobho wokuwelda umbhobho.

-- Kunyanzelekile ukuba ube kude nesakhelo esisisiseko.

--- qaphela ukuba bonke abantu abajikeleze umatshini bakumgama wokhuseleko.

---abasebenzi bezakhono mabagcine imithetho yokhuseleko.

Isondlo

| Into | Inkcazo | Hlola phambi kokusetyenziswa | Inyanga yokuqala | Rhoqo kwiinyanga ezi-6 | Qho ngonyaka |

| Isixhobo sokucwangcisa | Buyisela i-blade okanye ihlanjwe kwakhona Jonga ukuba intambo yophukile Jonga ukuba uqhagamshelo lomatshini luyekile |

●

|

● |

| ● ●

|

| Isitya sokufudumeza | Jonga intambo kunye neendawo zokuhlangana Coca umphezulu wepleyiti yokufudumeza, phinda unxibe i-PTFE umaleko kwakhona ukuba kuyimfuneko Jonga ukuba uqhagamshelo lomatshini luyekile | ● ●

|

● |

|

●

|

| Inkqubo yokulawula ubushushu | Khangela isalathisi sobushushu Jonga ukuba intambo yophukile |

● |

|

| ● ● |

| Inkqubo ye-hydraulic | Hlola igeyiji yoxinzelelo Jonga ukuba kudityaniswe umbhobho we-oyile ukuvuza, qinisa kwakhona okanye ukutshintshwa kwetywina Coca isihluzo Jonga ioyile ukuba ayikho Guqula ioli Khangela ukuba umbhobho weoyile wophukile na |

●

●

● |

|

●

| ●

● ●

|

| Isiseko Isakhelo | Jonga ukuba isikrufu sokuqinisa kwisiphelo se-axis yesakhelo sikhululekile na Tshafaza ipeyinti ye-antirust kwakhona ukuba kuyimfuneko |

●

|

●

|

●

|

● |

| Amandla Ubonelelo | Cinezela iqhosha lokuvavanya lomkhuseli wesekethe ukujonga ukuba umkhuseli wesiphaluka uyasebenza ngokuqhelekileyo Jonga ukuba intambo yophukile | ● ● |

|

● |

|