SDY355 BUTT FUSION Welding UMACHINE ISIKHOKELO SOKUSEBENZA

Inkcazo ekhethekileyo

Ngaphambi kokusebenzisa umatshini, nabani na kufuneka afunde le nkcazo ngononophelo kwaye ayigcine kakuhle ukuqinisekisa ukhuseleko lwesixhobo kunye nokhuseleko lwabanye.

2.1 Umatshini usetyenziselwa ukuwelda imibhobho eyenziwe kwi-PE, PP, PVDF kwaye ayinakusetyenziselwa ukuwelda izinto ngaphandle kwenkcazo, ngaphandle koko umatshini unokonakala okanye kubangele ingozi ethile.

2.2 Ungawusebenzisi umatshini kwindawo enengozi yokudubula

2.3 Lo matshini mawuqhutywe ngabasebenzi abanoxanduva, abaqeqeshiweyo nabaqeqeshiweyo.

2.4 Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

2.5 Umatshini usebenza nge-220V±10%, i-50 Hz. Ukuba kufuneka kusetyenziswe ucingo olwandisiweyo, kufuneka lube necandelo elilothe elaneleyo ngokobude balo.

2.6 Phambi kokuba usebenzise umatshini, gcwalisa 46# ioyile yolwelo olwenziwa ngamanzi. Qinisekisa ukuba ioli ye-hydraulic yanele ukusebenza; inqanaba leoli kufuneka libe yi-2/3 yetanki. Faka enye indawo yesivalo setanki yeoli ngentsimbi ebomvu yeplastiki yokopha ikepusi okanye uxinzelelo alunakubanjwa.

Ukhuseleko

3.1 Qaphela xa usebenza kwaye uhambisa umatshini ngokwemigaqo yonke yokhuseleko kulo myalelo.

3.1.1 Qaphela xa usebenzisa

l Umsebenzisi kufuneka abe ngabasebenzi abanoxanduva nabaqeqeshiweyo.

l Hlola ngokupheleleyo kwaye ugcine umatshini ngonyaka ukhuseleko kunye nokuthembeka komatshini.

l Indawo yokusebenza emdaka nekhalayo ayinakuthoba nje ukusebenza kakuhle, kodwa ibangele ingozi ngokulula, ngoko ke kubalulekile ukugcina indawo yokusebenza icocekile kwaye akukho miqobo.

3.1.2 Amandla

Ibhokisi yokuhambisa umbane kufuneka ibe nesiphazamisi somhlaba esinomgangatho ofanelekileyo wokhuseleko lombane. Zonke izixhobo zokukhusela ukhuseleko ziboniswa ngamagama okanye amanqaku aqondakala lula.

Umhlaba: Indawo yonke kufuneka yabelane ngocingo olufanayo lomhlaba kwaye inkqubo yoqhagamshelo lomhlaba kufuneka igqitywe kwaye ivavanywe ngabantu abaqeqeshiweyo.

3.1.3 Ukudityaniswa komatshini kumandla

Umatshini wokudibanisa ikhebula kumandla kufuneka ube yi-concussion yomatshini kunye nobungqina bokubola kweekhemikhali. Ukuba ucingo olwandisiweyo lusetyenzisiwe, kufuneka lube necandelo elikhokelayo elaneleyo ngokobude balo.

3.1.4 Ukugcinwa kwezixhobo zombane

Ngomnci. iingozi, zonke izixhobo kufuneka zisetyenziswe kwaye zigcinwe ngokuchanekileyo ngolu hlobo lulandelayo:

※Kuphephe ukusebenzisa ucingo lwexeshana olungahambelaniyo nomgangatho

※ Musa ukubamba iinxalenye ze-electrophorus

※ Yalela ukutsalwa ngaphandle kwentambo ukuze uqhawule

※ Yalela ukurhuqa iintambo zezixhobo zokuphakamisa

※ Musa ukubeka into enzima okanye ebukhali kwiintambo, kwaye ulawule ubushushu bekhebula ngaphakathi kokunciphisa ubushushu (70 ℃)

※ Musa ukusebenza kwindawo emanzi. Khangela ukuba i-groove kunye nezihlangu zomile.

※ Musa ukutshiza umatshini

3.1.5 Qwalasela imeko yobushushu bomatshini ngamaxesha athile

※ Jonga ukugquma kweentambo ngokukodwa amanqaku akhutshiweyo

※ Musa ukusebenzisa umatshini phantsi kweemeko ezinzima.

※ Jonga ukuba iqhosha lokuvuza lisebenza kakuhle ubuncinci ngeveki.

※ Jonga umhlaba womatshini ngabasebenzi abafanelekileyo

3.1.6 Coca kwaye ujonge umatshini ngononophelo

※ Musa ukusebenzisa izinto (ezifana ne-abrasive, kunye nezinye i-solvents) ukonakalisa i-insulation ngokulula xa ucoca umatshini.

※ Qinisekisa ukuba amandla avaliwe xa ugqiba umsebenzi.

※ Qinisekisa ukuba akukho monakalo kumatshini phambi kokuba uphinde uwusebenzise.

Ukuba kuphela ukulandela okukhankanywe ngasentla, isilumkiso sinokusebenza kakuhle.

3.1.7 Ukuqala

Qinisekisa ukuba iswitshi yomatshini ivaliwe phambi kokuba uyivule.

3.1.8 Umntu ongaqeqeshwanga akavumelekanga ukuba asebenzise umatshini nangaliphi na ixesha.

3.2.IiNgozi ezinokuthi zibe kho

3.3.1 Umatshini wokudityaniswa kwempundu olawulwa yiyunithi yehydraulic:

Lo matshini usebenza kuphela ngumntu oyingcali okanye abanye abanesatifikethi sokusebenza, kungenjalo ingozi engafunwayo inokubangelwa.

3.3.2 Icwecwe lokufudumeza

Ubushushu obukhulu bunokufikelela kwi-270 ℃, ke ezi zinto zilandelayo kufuneka ziqatshelwe:

------Nxiba iiglavu zokhuseleko

-------Ungaze ubambe umphezulu wepleyiti yokufudumeza

3.3.3 Isixhobo sokucwangcisa

Ngaphambi kokucheba imibhobho, iziphelo zemibhobho kufuneka zicocwe, ngakumbi ukucoca isanti okanye enye idrafu ekhalayo ejikeleze iziphelo. Ngokwenza oku, ubomi bomphetho bunokwandiswa, kwaye kwakhona ukuthintela ukucheba ukuphonswa ngaphandle kwabantu abasengozini.

3.3.4 Isakhelo esiSisiseko:

Qinisekisa ukuba imibhobho okanye izixhobo zilungiswe ngokuchanekileyo ukuze ufumane ulungelelwaniso olufanelekileyo. Xa ujoyina imibhobho, umqhubi kufuneka agcine indawo ethile kumatshini wokhuseleko lwabasebenzi.

Ngaphambi kokuthutha, qiniseka ukuba zonke iiclamps zilungiswe kakuhle kwaye azikwazi ukuwa phantsi ngexesha lokuthutha.

Landela onke amanqaku okhuseleko kumatshini.

Iinkcazelo

Umatshini uqukethe isakhelo esisisiseko, iyunithi ye-hydraulic, ipleyiti yokufudumeza, isixhobo sokucwangcisa kunye nenkxaso.

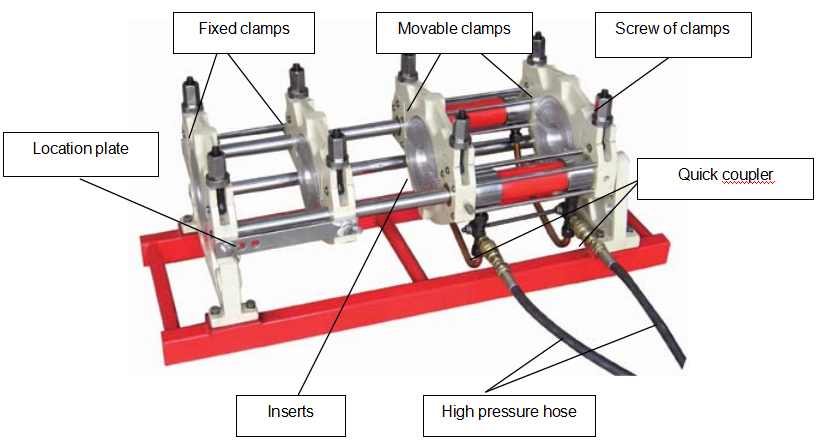

5.1 Isakhelo

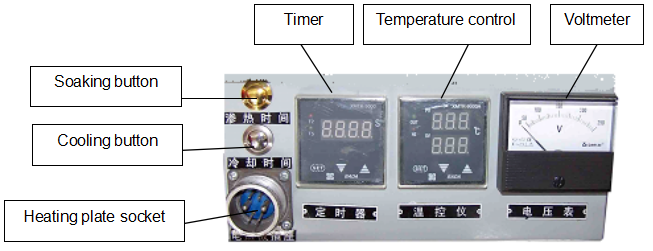

5.2 Isixhobo sokucwangcisa kunye nepleyiti yokufudumeza

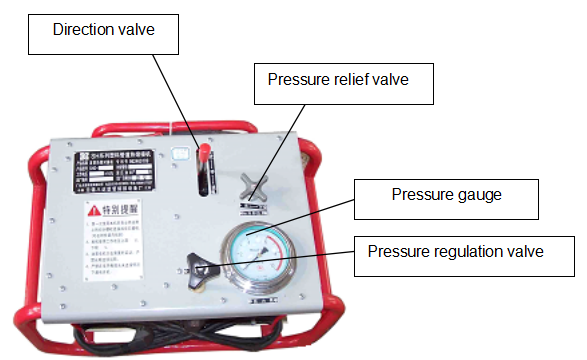

5.3 Iyunithi ye-hydraulic

Umyalelo wokusetyenziswa

6.1 Isixhobo sonke kufuneka sibekwe kwinqwelomoya ezinzileyo neyomileyo ukuze isebenze.

6.2 Ngaphambi kokuba usebenze qinisekisa ezi zinto zilandelayo:

u Umatshini ukwimeko ezilungileyo

u Amandla ahambelana neemfuno ngokuhambelana nomatshini wokudityaniswa kweempundu

u Intambo yamandla ayophukanga okanye inxibe

u Zonke izixhobo ziqhelekile

u Iincakuba zesixhobo sokucwangcisa zibukhali

u Zonke iindawo eziyimfuneko kunye nezixhobo ziyafumaneka

6.3 Uqhagamshelwano nokulungiselela

6.3.1 Qhagamshela isakhelo esisisiseko kwiyunithi yehydraulic ngabadibanisa ngokukhawuleza.

6.3.2 Qhagamshela umgca wepleyiti yokufudumeza kwibhokisi yombane kwiyunithi yehydraulic.

6.3.3 Qhagamshela umgca wepleyiti yokufudumeza kwipleyiti yokufudumeza.

6.3.4 Fakela izinto ezifakelweyo ezifanelekileyo ukwenza isakhelo ngokobubanzi bangaphandle bemibhobho/izifakelo.

6.3.5 Ngokweemfuno zenkqubo yokufakelwa kunye ne-welding, setha ubushushu kwisilawuli sobushushu kunye nexesha lokubeka ixesha. (Jonga icandelo 7 le ncwadana).

6.4 Amanyathelo okuwelda

6.4.1 Imibhobho

Ngaphambi kwe-welding, okokuqala, khangela ukuba izinto eziphathekayo kunye nebakala loxinzelelo zizinto ezifunekayo. Okwesibini, khangela ukuba kukho imikrwelo okanye iintanda kumphezulu wemibhobho/ufakelo. Ukuba ubunzulu bemikrwelo okanye i-fissures budlula i-10% yobukhulu bodonga, nqunqa icandelo lemikrwelo okanye i-fissures. Coca imiphezulu yombhobho ngelaphu elicocekileyo ukugcina iziphelo zombhobho zicocekile.

6.4.2 Ukuklina

Beka imibhobho / izixhobo ezifakwe kwifreyimu kwaye ugcine iziphelo ezifakwe kwi-welded zibe nobude obufanayo (akukho mphumo kwisicwangciso kunye nokufudumeza kombhobho). Umbhobho ophuma kwisakhelo esisisiseko kufuneka uxhaswe kwi-axial ephakathi ye-clamps. Qinisa izikrufu zeclamps ukulungisa imibhobho/izifakelo.

6.4.3 Lungisa uxinzelelo

Vula ngokupheleleyo ivalve yolawulo loxinzelelo ngokupheleleyo, tshixa ivalve yokujonga ujingi ngokuqinileyo kwaye emva koko utyhale phambili ivalve yendlela ngeli xesha uhlengahlengise ivalve yokulawula uxinzelelo de isilinda siqale ukuhamba, ngeli xesha uxinzelelo kwinkqubo luxinzelelo lokutsala.

Vula ivalve yokulawula uxinzelelo ngokupheleleyo, tshixa ivalve yokujonga ujingi ngokuqinileyo kwaye emva koko utyhale phambili ivalve yendlela ngeli xesha uhlengahlengise ivalve yokulawula uxinzelelo ukuseta uxinzelelo lwenkqubo lulingana nokutsala uxinzelelo lokongeza uxinzelelo.

6.4.4 Ukucwangcisa

Vula imibhobho/iziphelo zofakelo emva kokujika ivalve yokujonga ijingi ngokunxamnye newotshi ukuya ekupheleni. Beka isixhobo sokucwangcisa phakathi kwemibhobho/iziphelo zofakelo kwaye uyivule, vala imibhobho/iziphelo zofakelo ngokusebenza kwivalvu yendlela ngeli xesha ujike ngokucotha ujingi jonga ivalve ngasekunene de kubekho ukucheba okuqhubekayo okuvela macala omabini. Jika ivalve yokujingi ngokuchasene newotshi ukukhulula uxinzelelo, emzuzwini kamva vula isakhelo, cima isixhobo sokucwangcisa kwaye usisuse.

Vala imibhobho / iziphelo ezifanelekileyo kwaye ukhangele ukulungelelaniswa kwazo. Ukungalungi kakuhle okukhulu akufanele kudlule i-10% yobukhulu bodonga, kwaye inokuphuculwa ngokukhulula okanye ukuqinisa izikhonkwane ze-clamps. Umsantsa phakathi kweziphelo zemibhobho emibini akufanele udlule i-10% yobukhulu bodonga; kungenjalo imibhobho/izifakelo kufuneka zicwangciswe kwakhona.

Isilumkiso: Ubukhulu be-shavings kufuneka bube ngaphakathi kwe-0.2 ~ 0.5 mm kwaye bunokulungelelaniswa ngokulungelelanisa ukuphakama kwezixhobo zokucwangcisa izixhobo.

6.4.5 Ukufudumeza

Sula uthuli okanye ukuqhekeza kumphezulu wepleyiti yokufudumeza (Isilumkiso: Musa ukonakalisa umaleko we-PTFE kumphezulu wepleyiti yokufudumeza.), kwaye uqinisekise ukuba ubushushu bufikelele kwefunekayo.

Beka ipleyiti yokufudumeza phakathi kweziphelo zepayipi emva kokuba ifikelele kwiqondo lokushisa elifunekayo. Vala imibhobho/iziphelo zofakelo ngevalvu yendlela yokusebenza kwaye unyuse uxinzelelo kuxinzelelo oluchaziweyo ngokujiwuzisa ivelufa yolawulo loxinzelelo de intsimbi ifike kubude obuchaziweyo.

Jika ivalve yokujonga ujingi ngokunxamnye newotshi ukunciphisa uxinzelelo (ungabi ngaphezu koxinzelelo lokutsalwa) kwaye ujike ivalve yokukhangela ijingi kwicala lewotshi ukuya ekupheleni.

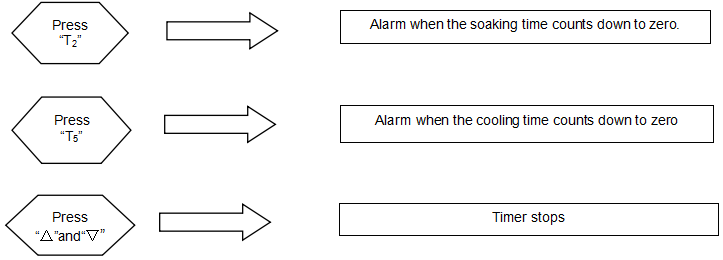

Cofa iqhosha elithi “T2”, ixesha lokufunxa liqala ukubala kwaye ixesha liya kubala lihle liye kutsho ku-zero ngesibini, emva koko i-buzzer iya kubhuza (bona icandelo 7)

6.4.6 Ukudibanisa kunye nokupholisa

Vula isakhelo kwaye ukhuphe ipleyiti yokufudumeza kwaye uvale iziphelo ezimbini zokunyibilika ngokukhawuleza.

Gcina ibha yevalve yendlela kwindawo esondeleyo kwi-2 ~ 3 imizuzu, beka ibha yevalve yolwalathiso kwindawo ephakathi kwaye ucinezele iqhosha ("T5") ukubala ixesha lokupholisa de liphele. Ngeli xesha, umatshini uya kunika i-alamu kwakhona. Nciphisa uxinzelelo, khulula isikrufu sezibambeli emva koko ukhuphe imibhobho edibeneyo.

Isibali-xesha kunye nesiLawuli soBubushushu

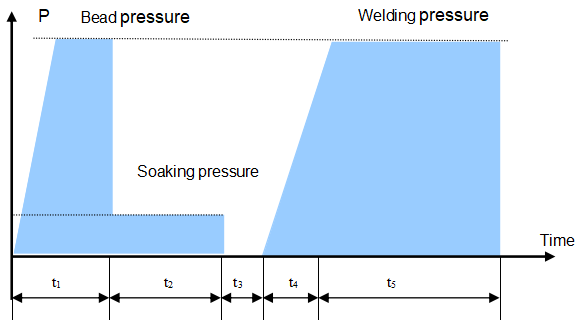

Ukuba enye iparameters itshintshiwe, njenge-diameter yangaphandle, i-SDR okanye izinto zemibhobho, ixesha lokucwina kunye nexesha lokupholisa kufuneka libuyiselwe ngokwemigangatho ye-welding.

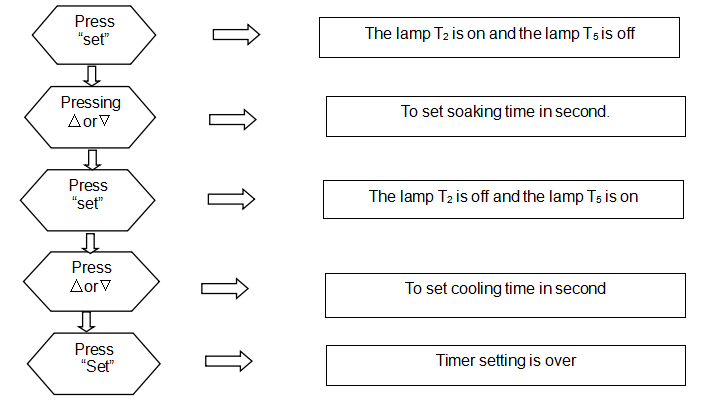

7.1 Ukusetha ixesha

7.2 Umyalelo wokusetyenziswa

7.3 Ukusetha isilawuli sobushushu

1) Cinezela "SET" ngaphezu kwemizuzwana ye-3 de "sd" iboniswe kwifestile ephezulu

2) Cinezela "∧" okanye "∨" ukutshintsha ixabiso elichaziweyo (cofa "∧" okanye "∨" ngokuqhubekayo, ixabiso liya kudibanisa okanye lisuse ngokuzenzekelayo)

3) Emva kokuseta, cofa u-"SET" ukuze ubuyele ekubekeni iliso kunye nokulawula ujongano

Isalathiso soMgangatho weWelding (DVS2207-1-1995)

8.1 Ngenxa yokungafani kumgangatho we-welding kunye nezinto ze-PE, ixesha kunye noxinzelelo luyahluka kwizigaba ezahlukeneyo ze-welding. Iphakamisa ukuba iiparameters ze-welding zangempela kufuneka zinikezelwe yimibhobho kunye nabavelisi bezinto zokufakelwa.

8.2 Ubushushu obunikwe kwi-welding yemibhobho eyenziwe kwi-PE, PP kunye ne-PVDF yi-DVS yomgangatho ophakathi ukusuka kwi-180 ℃ ukuya kwi-270 ℃. Ubushushu besicelo sepleyiti yokufudumeza bungaphakathi kwe-180℃230℃, kunye nobukhulu bayo. ubushushu bomphezulu bunokufikelela kuma-270℃.

8.3 Ireferensi yomgangatho weDVS2207-1-1995

| Ubunzima bodonga (mm) | Ubude bentsimbi (mm) | Uxinzelelo lokwakha amaso (MPa) | Ixesha lokuhamba t2(umzuzwana) | Uxinzelelo lokuntywila (MPa) | Ukutshintsha kwexesha t3(umzuzwana) | Ixesha lokwakha uxinzelelo t4(umzuzwana) | Uxinzelelo lweWelding (MPa) | Ixesha lokupholisa t5(min) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45 ~ 70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7 ~12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 ~8 | 6 ~8 | 0.15±0.01 | 10~16 |

| 12 ~ 19 | 2.0 | 0.15 | 120 ~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10~12 | 11 ~ 14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12 - 16 | 14 ~ 19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16 ~ 20 | 19 ~ 25 | 0.15±0.01 | 45 ~ 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~700 | ≤0.02 | 20 ~ 25 | 25 ~ 35 | 0.15±0.01 | 60 ~ 80 |

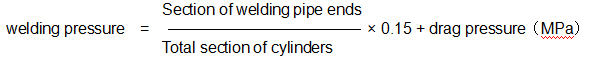

Phawula:Uxinzelelo lwe-bead build-up kunye noxinzelelo lwe-welding kwifom luxinzelelo olucetyiswayo lwe-interface, uxinzelelo lwegeyiji kufuneka lubalwe ngale fomyula ilandelayo.

Amabinzana:

Uhlalutyo olungalunganga kunye nezisombululo

8.1 Iingxaki zomgangatho wamalungu rhoqo zihlalutya:

8.2 Amaxesha okugcinwa nokuhlolwa

8.2.1 Ugcino

※ Ukwaleka ipleyiti yokufudumeza

Nceda uqaphele ukuphatha ipleyiti yokufudumeza. Gcina umgama othile kude nepleyiti yokufudumeza. Ukucocwa komphezulu wayo kufuneka kwenziwe ngomphezulu osafudumeleyo ngokusebenzisa ilaphu elithambileyo okanye iphepha, kunqandwe izinto ezirhabaxa ezinokuthi zonakalise isambatho.

Ngamathuba aqhelekileyo jonga ngolu hlobo lulandelayo

1) Coca umphezulu ngokusebenzisa isicoci esikhawulezayo sokuphuma sibe ngumphunga (utywala)

2) Khangela ukuqiniswa kwezikrufu kunye nekhebula kunye nemeko yeplagi

3) Qinisekisa ubushushu bomphezulu wawo ngokusebenzisa iskena se-infrared-ray

※ isixhobo sokucwangcisa

Kucetyiswa ngamandla ukuba uhlale ucocekile iincakuba kwaye uhlambe iipulleys ngokusebenzisa i-detergent. Ngexesha eliqhelekileyo, yenza umsebenzi wokucoca ngokupheleleyo.

※ iyunithi Hydraulic

Yigcine ngolu hlobo lulandelayo

1) Khangela ngamaxesha athile inqanaba leoli

2) Buyisela ioli ngokupheleleyo zonke iinyanga ezi-6

3) Gcina itanki kunye nesekethe yeoli icocekile

8.2.2 Ugcino kunye noHlolo

Ukuhlolwa okuqhelekileyo

| Into | Inkcazo | Hlola phambi kokusetyenziswa | Ekuqaleni inyanga | Rhoqo kwiinyanga ezi-6 | Yonke unyaka |

| Isixhobo sokucwangcisa | I-Mill okanye itshintshe i-blade Buyisela intambo ukuba yophukile Phinda uqinise imidibaniso yoomatshini |

● ● |

● |

| ● ●

|

| Isitya sokufudumeza | Udibanise intambo kunye nesokethi Coca umphezulu wepleyiti yokufudumeza, phinda unxibe i-PTFE umaleko kwakhona ukuba kuyimfuneko Phinda uqinise imidibaniso yoomatshini | ● ●

● |

● |

|

●

|

| Temp. inkqubo yolawulo | Khangela isalathisi sobushushu Buyisela intambo ukuba yophukile |

● |

|

| ● ● |

| Inkqubo ye-hydraulic | Hlola igeyiji yoxinzelelo Tshintsha amatywina ukuba iyunithi yolwelo olwenziwa ngamanzi aphantsi iyavuza Coca isihluzo Qinisekisa ukuba ioli yanele ukusebenza Guqula ioli ye-hydraulic Thatha indawo ukuba i-hose yeoli iphukile |

● ● ● |

|

● | ● ●

● ●

|

| Isiseko Isakhelo | Phinda uqinise izikrufu kwisiphelo se-axis yesakhelo Tshafaza ipeyinti ye-antirust kwakhona ukuba kuyimfuneko | ●

| ●

| ●

|

● |

| Amandla Ubonelelo | Cinezela iqhosha lokuvavanya lomkhuseli wesekethe ukuqinisekisa ukuba inokusebenza ngokuqhelekileyo Buyisela intambo ukuba yophukile | ●

● |

|

● |

|

“●”………… ixesha lolondolozo

9.3 Ukuhlalutya ukungasebenzi rhoqo kunye nezisombululo

Ngexesha lokusetyenziswa, iyunithi ye-hydraulic kunye neeyunithi zombane zinokubonakala iingxaki ezithile. Ukungasebenzi kakuhle kudweliswe ngolu hlobo lulandelayo:

Nceda usebenzise izixhobo ezincanyathiselwe, iinxalenye ezisecaleni okanye ezinye izixhobo ezinesatifikethi sokhuseleko ngelixa ulungisa okanye utshintsha iindawo. Izixhobo kunye neendawo ezisecaleni ngaphandle kwesiqinisekiso sokhuseleko azivumelekanga ukuba zisetyenziswe.

| Ukungasebenzi kakuhle kweyunithi ye-hydraulic | |||

| No | iinkqubo zininzi | uhlalutyo lokungasebenzi kakuhle | Izisombululo |

| 1 | Injini yepompo ayisebenzi |

| |

| 2 | Ipompo motor ijikeleza ngokucothayo kakhulu ngengxolo engaqhelekanga |

| 1. Qinisekisa ukuba umthwalo wemoto ungaphantsi kwe-3 MPa 2. Lungisa okanye ubuyisele impompo 3. Coca isihluzo 4. Khangela ukungazinzi kwamandla |

| 3 | Isilinda sisebenza ngokungaqhelekanga |

| |

| 4 | Ukuvuza kwesilinda | 1. Iringi yeoli iyimpazamo 2. Isilinda okanye ipiston yonakaliswe kakubi | 1. Faka endaweni yeringi yeoli 2. Faka endaweni yesilinda |

| 5 | Uxinzelelo alunakunyuswa okanye ukuguquguquka kukhulu kakhulu | 1. Undoqo wevalve yokuphuphuma uvalekile. 2. Impompo iyavuza. 3. Ukutyibilika okudityanisiweyo kwempompo kuyayekiswa okanye i-key groove iyatyibilika. 4. Ivalve yokunciphisa uxinzelelo ayitshixwanga | 1. Coca okanye ubuyisele undoqo wevalve yokuphuma kwamanzi 2. Faka indawo yempompo 3. Faka indawo ye-joint slack 4. Tshixa ivalve |

|

Ukungasebenzi kakuhle kweeyunithi zombane | |||

| 1 | Umatshini awusebenzi |

| 1. Jonga intambo yamandla 2. Jonga amandla okusebenza 3. Vula isiphazamisi sempazamo emhlabeni |

| 2 | Iihambo zokutshintsha iimpazamo eziphantsi |

| 1. Jonga iintambo zombane 2. Jonga izinto zombane. 3. Jonga isixhobo sokhuseleko lwamandla aphezulu |

| 3 | Ukunyuka kobushushu obungaqhelekanga | 1. Ukutshintsha kokulawula ubushushu kuvuliwe 2. Uluvo (pt100) aluqhelekanga. Ixabiso lokumelana ne-4 kunye ne-5 yesokhethi yepleyiti yokufudumeza kufuneka ibe ngaphakathi kwe-100 ~ 183Ω 3. Intonga yokufudumeza ngaphakathi kwipleyiti yokufudumeza ayiqhelekanga. Ukuchasana phakathi kwe-2 kunye ne-3 kufuneka ibe ngaphakathi kwe-23Ω. Ukumelana ne-insulation phakathi kwentloko yentonga yokufudumeza kunye negobolondo langaphandle kufuneka libe ngaphezu kwe-1MΩ 4. Ukuba ufundo lwesilawuli seqondo lobushushu lungaphezulu kwe-300℃, nto leyo ebonisa ukuba isivamvo soluvo singonakala okanye uqhagamshelo lukhululwe. Ngaba umlawuli weqondo lokushisa kufuneka abonise i-LL, ebonisa ukuba inzwa inesekhethi emfutshane. Ngaba umlawuli weqondo lokushisa ubonise i-HH, ebonisa ukuba isiphaluka senzwa sivuliwe. 5. Lungisa ubushushu ngeqhosha elibekwe kwisilawuli sobushushu.

| 1. Jonga uqhagamshelwano lwabafowunelwa 2. Faka indawo yoluvo

3. Buyisela ipleyiti yokufudumeza

4. Faka endaweni yesilawuli sobushushu

5. Jonga kwiindlela zokuseta ubushushu 6. Khangela kwaye ubuyisele abafowunelwa ukuba kukho imfuneko |

| 4 | Ukuphulukana nolawulo xa ufudumeza | Ukukhanya okubomvu kuyakhanya, kodwa iqondo lobushushu lisanyuka, oko kungenxa yokuba isinxibelelanisi sisiphoso okanye amalungu 7 kunye no-8 akakwazi ukuvula xa ufumana ubushushu obufunekayo. | Buyisela isilawuli sobushushu

|

| 5 | Isixhobo sokucwangcisa asijikelezi | Umda wokutshintsha awusebenzi okanye iindawo zomatshini zesixhobo sokucwangcisa ziyanqunyulwa. | Buyisela isitshixo somda wesixhobo sokucwangcisa okanye i-sprocket encinci |