SDG315 380 igeyiji yoxinzelelo lwedijithali

Ngokufutshane

Kanye kunye nepropati yezinto ze-PE eziqhubekayo zokugqibelela kunye nokuphakamisa, umbhobho we-PE usetyenziswa kakhulu kwigesi kunye nokunikezelwa kwamanzi, ukuchithwa kwamanzi amdaka, imboni yeekhemikhali, imigodi kunye nokunye.

Umzi-mveliso wethu uphanda kwaye uphuhlisa umatshini we-SD weplastiki yombhobho we-butt fusion olungele i-PE, PP, kunye ne-PVDF ngaphezulu kweminyaka elishumi.

Namhlanje, iimveliso zethu zibandakanya iintlobo ezisibhozo kunye neentlobo ezingaphezu kwama-20 ezisebenza kulwakhiwo lwemibhobho yeplastiki kwaye zenze izifakelo kwindawo yokusebenzela ngolu hlobo lulandelayo:

| SHS series socket welder | SDC series Band wabona |

| SD series manual butt fusion machine | SDG series workshop welding machine |

| SDY series butt fusion machine | Series izixhobo ezikhethekileyo |

| QZD series Auto-butt fusion machine | SHM uthotho isali fusion umatshini |

Le ncwadana yenzelwe umatshini we-SDG315 weplastiki wemibhobho yokusebenzela. Ukuze uphephe naluphi na uhlobo lwengozi ebangelwa ngumbane okanye ngoomatshini. Kucetyiswa ukuba ufunde ngononophelo kwaye ulandele le migaqo yokhuseleko ilandelayo phambi kokuba usebenze umatshini.

Inkcazo ekhethekileyo

Ngaphambi kokusebenzisa umatshini, nabani na kufuneka afunde le nkcazo ngononophelo kwaye ayigcine kakuhle ukuqinisekisa ukhuseleko lwesixhobo kunye nokhuseleko lwabanye.

2.1 Umatshini usetyenziselwa ukuwelda imibhobho eyenziwe kwi-PE, PP, PVDF kwaye ayinakusetyenziselwa ukuwelda izinto ngaphandle kwenkcazo, ngaphandle koko umatshini unokonakala okanye kubangele ingozi ethile.

2.2 Ungawusebenzisi umatshini kwindawo enengozi yokudubula

2.3 Lo matshini mawuqhutywe ngabasebenzi abanoxanduva, abaqeqeshiweyo nabaqeqeshiweyo.

2.4 Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

2.5 Kufuneka umatshini380V± 10%, 50 Hz unikezelo lwamandla. Ukuba intambo yokwandisa kufuneka isetyenziswe, kufuneka kubekho icandelo elaneleyo ngokobude babo.

Ukhuseleko

3.1 amanqaku okhuseleko

La manqaku alandelayo agxininiswe kumatshini:

3.2 ImiGaqo yoKhuseleko

Qaphela xa usebenza kwaye uhambisa umatshini ngokwemigaqo yonke yokhuseleko kulo myalelo.

3.2.1 Qaphela xa usebenzisa

l Umsebenzisi kufuneka abe ngabasebenzi abanoxanduva nabaqeqeshiweyo.

l Hlola ngokupheleleyo kwaye ulondoloze umatshini ngonyaka ukwenzela ukhuseleko kunye noomatshini

ukuthembeka.

3.2.2Amandla

Ibhokisi yokuhambisa umbane kufuneka ibe nesiphazamisi somhlaba esinomgangatho ofanelekileyo wokhuseleko lombane. Zonke izixhobo zokukhusela ukhuseleko ziboniswa ngamagama okanye amanqaku aqondakala lula.

3.2.3 Cima umbane phambi kokuba ususe isiciko sokhuseleko okanye inethi.

Ukudityaniswa komatshini kumandla

Umatshini wokudibanisa ikhebula kumandla kufuneka ube yi-concussion yomatshini kunye nobungqina bokubola kweekhemikhali. Ukuba ucingo olwandisiweyo lusetyenzisiwe, kufuneka lube necandelo elikhokelayo elaneleyo ngokobude balo.

Earthing: Isayithi yonke kufuneka yabelane ngocingo olufanayo lomhlaba kunye nenkqubo yokudibanisa umhlaba kufuneka igqitywe kwaye ihlolwe ngabantu abaqeqeshiweyo.

3.2.3Ukugcinwa kwezixhobo zombane

Ngomnci. iingozi, zonke izixhobo kufuneka zisetyenziswe kwaye zigcinwe ngokuchanekileyo ngolu hlobo lulandelayo:

※Kuphephe ukusebenzisa ucingo lwexeshana olungahambelaniyo nomgangatho

※ Musa ukubamba iinxalenye ze-electrophorus

※ Yalela ukutsalwa ngaphandle kwentambo ukuze uqhawule

※ Yalela ukurhuqa iintambo zezixhobo zokuphakamisa

※ Musa ukubeka into enzima okanye ebukhali kwiintambo, kwaye ulawule ubushushu bekhebula ngaphakathi kokunciphisa ubushushu (70 ℃)

※ Musa ukusebenza kwindawo emanzi. Khangela ukuba i-groove kunye nezihlangu zomile.

※ Musa ukutshiza umatshini

3.2.4 Qwalasela imeko yobushushu bomatshini ngamaxesha athile

※ Jonga ukugquma kweentambo ngokukodwa amanqaku akhutshiweyo

※ Musa ukusebenzisa umatshini phantsi kweemeko ezinzima.

※ Jonga ukuba iqhosha lokuvuza lisebenza kakuhle ubuncinci ngeveki.

※ Jonga umhlaba womatshini ngabasebenzi abafanelekileyo

3.2.5 Coca kwaye ujonge umatshini ngononophelo

※ Musa ukusebenzisa izinto (ezifana ne-abrasive, kunye nezinye i-solvents) ukonakalisa i-insulation ngokulula xa ucoca umatshini.

※ Qinisekisa ukuba amandla avaliwe xa ugqiba umsebenzi.

※ Qinisekisa ukuba akukho monakalo kumatshini phambi kokuba uphinde uwusebenzise.

Ukuba kuphela ukulandela okukhankanywe ngasentla, isilumkiso sinokusebenza kakuhle.

3.2.6 Ukuqala

Qinisekisa ukuba iswitshi yomatshini ivaliwe phambi kokuba uyivule.

3.2.7 Ukuqina kwamalungu

Qinisekisa ukuba imibhobho ilungiswe ngokuchanekileyo. Qinisekisa ukuba iyakwazi ukuhamba kakuhle kwaye uyithintele ekutyibilikeni ezantsi.

3.2.8 Indawo yokusebenza

Kuphephe ukusebenzisa umatshini kwindawo egcwele ipeyinti, igesi, umsi kunye ne-deoil, kuba ukosuleleka kwamehlo kunye nephecana lokuphefumla kuya kubangelwa.

Musa ukubeka umatshini kwindawo emdaka.

3.2.9 Ukhuseleko lwabasebenzi ngelixa besebenza

Susa ubucwebe kunye nemisesane, kwaye unganxibi mpahla ekhululekileyo kuphephe ukunxiba intambo yezihlangu, amadevu amade okanye iinwele ezinde ezinokubotshelelwa kumatshini.

Ukhuseleko lwabasebenzi ngelixa besebenza

3.3 Ukhuseleko lweZixhobo

Umatshini we-welding we-Hydraulic workshop welding usebenza kuphela yingcali okanye umsebenzi onesatifikethi esiqeqeshiweyo. Umntu oqhelekileyo unokonakalisa umatshini okanye abanye abakufutshane.

3.3.1 Ipleyiti yokufudumeza

l Ubushushu bomphezulu wepleyiti yokufudumeza bunokufikelela kwi-270℃.Ungakhe uyibambe ngokuthe ngqo ukunqanda ukutshiswa.

l Ngaphambi nasemva kokusebenzisa, coca umphezulu ngelaphu elithambileyo. Gwema izinto ezinqabileyo ezinokuthi zonakalise isambatho.

l Jonga intambo yokufudumeza intambo kwaye uqinisekise ubushushu bomphezulu.

3.3.2 Isixhobo sokucwangcisa

l Ngaphambi kokucheba imibhobho, iziphelo zemibhobho kufuneka zicocwe, ngakumbi ukucoca isanti okanye enye idrafu ekhalayo ejikeleze iziphelo. Ngokwenza oku, ubomi bomphetho bunokwandiswa, kwaye kwakhona ukuthintela ukucheba ukuphonswa ngaphandle kwabantu abasengozini.

l Qinisekisa isixhobo sokucwangcisa sitshixe ngokungqongqo ngeziphelo zemibhobho emibini

3.3.3 Isakhelo esingundoqo:

l Qinisekisa ukuba imibhobho okanye izifakelo zilungiswe ngokuchanekileyo ukufumana ulungelelwaniso olufanelekileyo.

l Xa ujoyina imibhobho, umqhubi kufuneka agcine indawo ethile kumatshini wokhuseleko lwabasebenzi.

l Ngaphambi kokuthutha, qiniseka ukuba zonke ii-clamps zilungiswe kakuhle kwaye azikwazi ukuwa phantsi ngexesha lokuthutha.

Uluhlu olusebenzayo kunye neeParameters zobuGcisa

| Uhlobo | SDG315 | |

| Izinto ze-welding | PE,PP,PVDF | |

| Ngaphandle Ububanzi uluhlu | ingqiniba (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm |

| itheyi (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

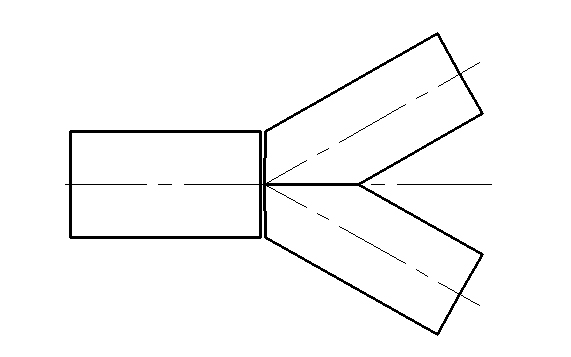

| umnqamlezo (DN, mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| IWyes 45&60° (DN,mm) | 90 110 125 140 160 180 200 225 250 280 315mm | |

| Ubushushu bendawo | -5 ~ 45℃ | |

| Ioli yeHydraulic | 40 - 50 (kinematic viscosity) mm2/s, 40℃) | |

| Ukunikezwa Amandla | ~380 V±10% | |

| Ukuphindaphinda | 50 Hz | |

| Iyonke yangoku | 13 A | |

| Amandla onke | 7.4 KW | |

| Bandakanya, ipleyiti yokufudumeza | 5.15 KW | |

| Isixhobo sokucwangcisa imoto | 1.5 KW | |

| Injini yeyunithi yeHydraulic | 0.75 KW | |

| Ukumelana nokugquma | >1MΩ | |

| Max. uxinzelelo lwehydraulic | 6 MPa | |

| Icandelo elipheleleyo leesilinda | 12.56 cm2 | |

| Max. ubushushu bepleyiti yokufudumeza | 270℃ | |

| Umahluko kubushushu bomphezulu wepleyiti yokufudumeza | ± 7℃ | |

| Isandi esingafunekiyo | <70 dB | |

| Itanki yeoli Umthamo | 55L | |

| Ubunzima bubonke(kg) | 995 | |

Iinkcazelo

Umatshini wokuwelda weworkshop unokuvelisa ingqiniba, tee, ukuwela umbhobho we-PE kwindawo yokusebenzela. Iziqhoboshi ezisemgangathweni zihambelana nobungakanani bemibhobho esemgangathweni ngokwe ISO161/1.

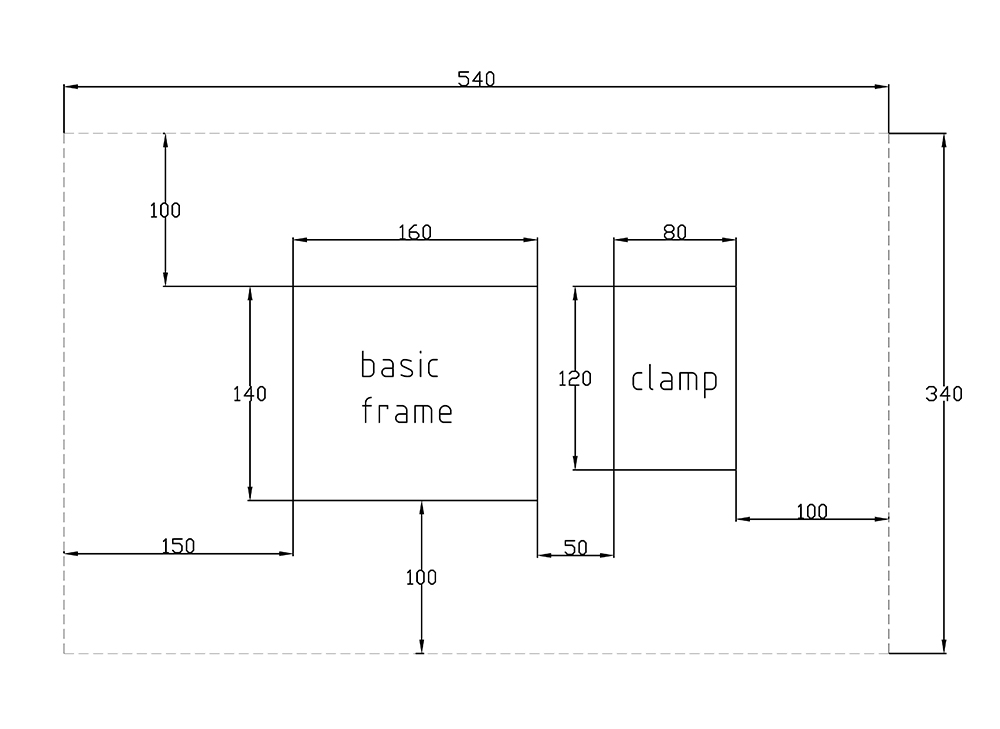

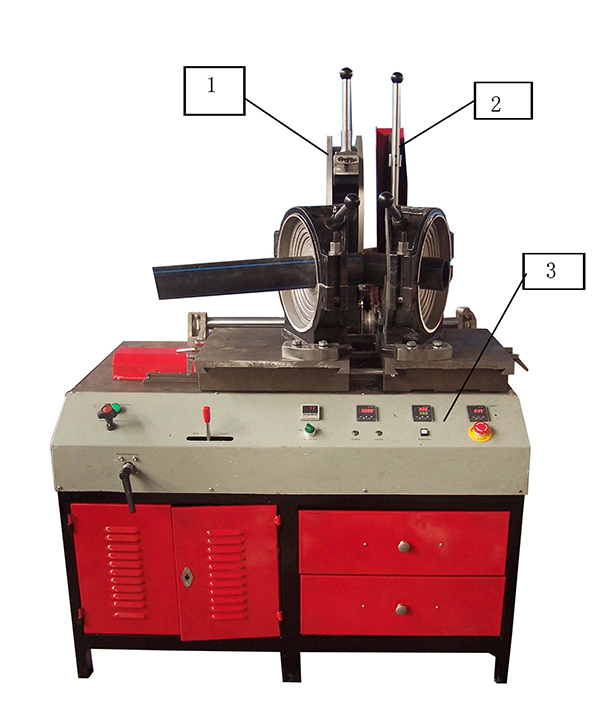

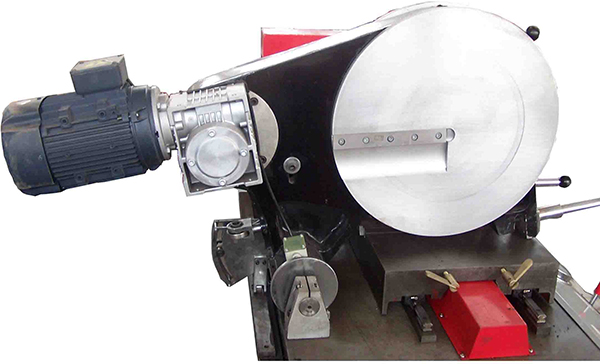

5.1 Umatshini ongundoqo

| 1. Isixhobo sokucwangcisa | 2. Ipleyiti yokufudumeza | 3. Iphaneli yokusebenza |

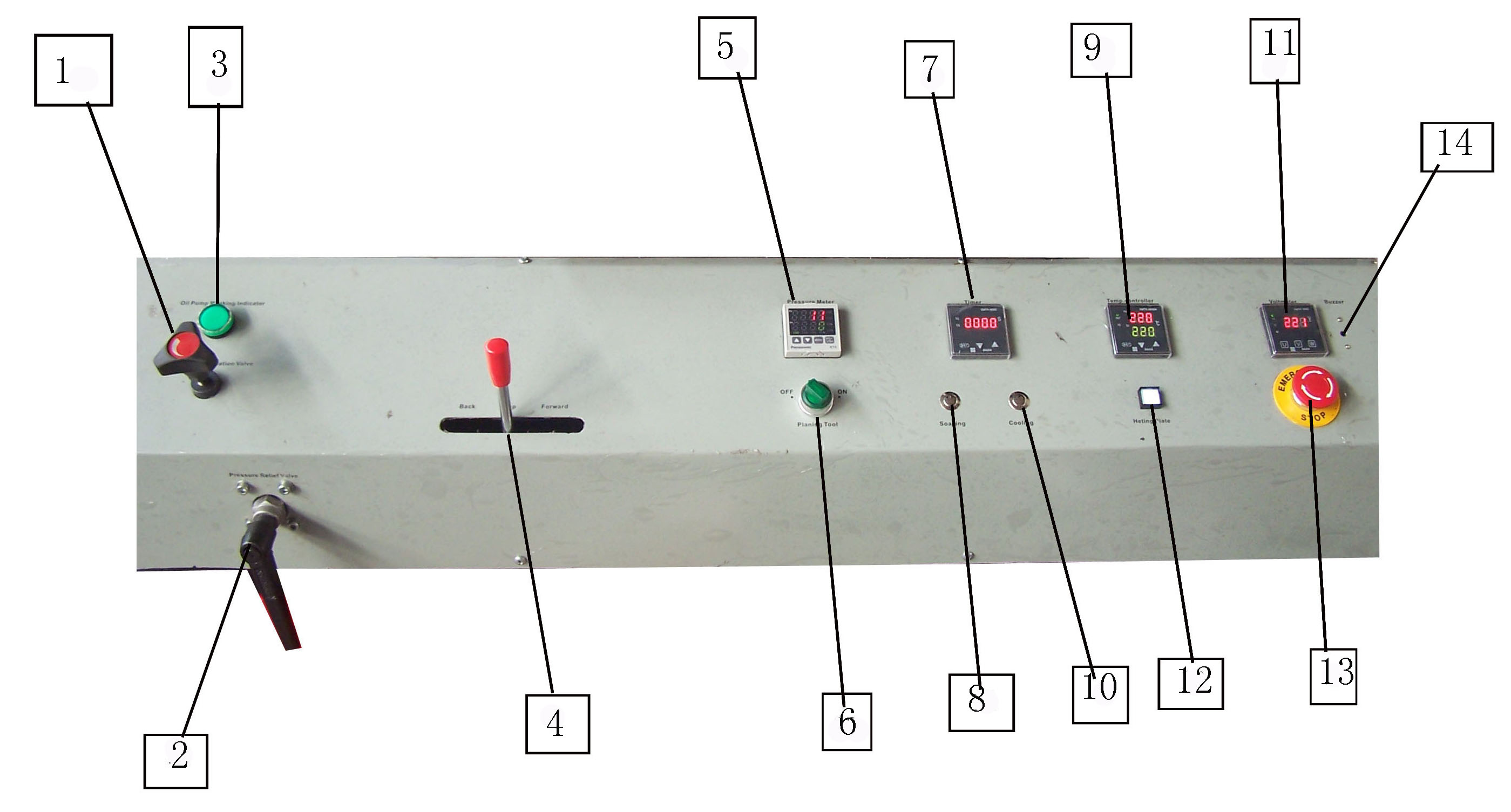

5.2 Iphaneli yokusebenza

| 1. IValve yoLawulo loxinzelelo | 2. IValve yokuNceda ngoxinzelelo | 3. Isalathisi sokuSebenza seMpompo ye-Oli | 4. IValve yoMkhombandlela |

| 5. Imitha yoxinzelelo lweDijithali | 6. Iqhosha lokucwangcisa | 7. Isibali-xesha | 8. Iqhosha leXesha lokuFaka |

| 9. Imitha yokulawula ubushushu | 10. Iqhosha leXesha lokupholisa | 11. I-Voltmeter | 12. Ukutshintsha ukufudumeza |

| 13. Ukuyeka ngokuNgxamisekileyo | 14. Buzzer |

Ukuhlohla

6.1 Ukuphakamisa kunye nokufakwa

Xa uphakamisa kwaye ufaka umatshini kufuneka ugcinwe ngokuthe tye, kwaye ungaze uhlehlise okanye uhlehlise ukuphepha umonakalo ongafunekiyo.

6.1.1 Ukuba i-forklift isetyenzisiwe, kufuneka ifakwe ngononophelo ukusuka ezantsi komtshini ngononophelo ukuphepha ukonakalisa umbhobho weoyile kunye nesekethe.

6.1.2 Xa uhambisa umatshini kwindawo yokufakela, i-mainframe kufuneka igcinwe izinzile kwaye inqamle.

6.1.3 Faka i-motor kwibhokisi yokunciphisa isixhobo sokucwangcisa kwaye ulungiswe ngezikrufu, eziboniswe kwi-Fig.3.

6.2 Uqhagamshelwano

Qinisekisa ukuba indawo yanele yokubeka umatshini kwaye ugcine umatshini wonke uthe tyaba kwaye uqinisekise uxhulumaniso oluchanekileyo lwazo zonke iisokethi, iintambo kunye nemibhobho xa ufaka umatshini.

6.2.1 Qhagamshela umatshini omkhulu kwibhokisi yombane.

Umzobo 4 Qhagamshela ipleyiti yokufudumeza kwibhokisi yombane

Umzobo 5 Qhagamshela isixhobo sokucwangcisa kwibhokisi yombane

6.2.2 Ukudibanisa intambo yomatshini kumandla, okuyizigaba ezintathu- iingcingo ezintlanu 380V 50HZ.

Ukhuseleko, umatshini kufuneka ufakwe emhlabeni ukusuka kwindawo ephantsi yomatshini.

6.2.3 Gcwalisa ioli yehydraulic ehluziweyo. Ukuphakama kweoli kufuneka kube ngaphezulu kwe-2/3 yobude bobubanzi be-gauge yomxholo.

Isilumkiso: Ukwenza umhlaba kufuneka kugqitywe ngabantu abaqeqeshiweyo.

Umyalelo wokusetyenziswa

Landela yonke imithetho yokhuseleko kumatshini. Umntu ongaqeqeshwanga akavumelekanga ukuba asebenzise umatshini.

7.1 Amandla

Vala isiphazamisi sempazamo emhlabeni

7.2 Qalisa impompo yeoli

Qala impompo yeoli ukuze ujonge indlela ejikelezayo. Ukuba i-gauge yoxinzelelo inokufundwa, ukujikeleza kulungile, ukuba akunjalo, ukutshintshisa nayiphi na iingcingo ezimbini eziphilayo.

7.3 Jonga kwaye ulungelelanise uxinzelelo lotsalo kunye nesantya sokuhamba sepleyiti yokutsala. Uxinzelelo lokusebenza lwenkqubo yi-6 MPa. Uxinzelelo lokujoyina lunokulungiswa ngevalve yokulawula uxinzelelo ebekwe kwipaneli yokulawula. Uxinzelelo lokucwangcisa kufuneka lwandiswe ngokuthe ngcembe, kwaye lugcine xa ukucheba okuqhubekayo kubonakala (kungabi mkhulu kakhulu). Isantya sokutya sepleyiti yokutsala sinokuhlengahlengiswa ngevalve yokutshekisha (ngaphakathi kwesiseko).

7.4 Ukufakwa kweeKlampu

Faka izihlalo ezibambekayo ezisekhohlo nasekunene (iiclamps zeeteyi okanye iingqiniba) ngokwezinto eziza kwenziwa.

1) Zilungise kuqala ngephini lokutshixa elidityaniswe nomatshini;

2) Lungisa i-angle kunye nesibambo sendawo ekhethekileyo;

3) Qinisa isikrufu sokutshixa ngesikrufu.

Ukuba izibophelelo zengqiniba zifuna ukusetyenziswa, zicinezele ngokuqinileyo ngepleyiti yokutshixa emva kokulungelelanisa i-engile.

7.5 Beka iqondo lokushisa elichaziweyo kwisilawuli seqondo lokushisa ngokwenkqubo ye-welding yepayipi. (Jonga icandelo 7.10)

7.6 Phambi kokunyusa okanye ukwehlisa isixhobo sokucwangcisa vula isixhobo sokutshixa kumqheba.

7.7 Imibhobho ebekwe kumatshini

7.7.1 Yahlula iiclamps zomatshini ngokusebenza kwilever yevalve eya ngakulo

7.7.2 Misa imibhobho kwiziqhoboshi uze uyiqinise; indawo phakathi kweziphelo zemibhobho emibini kufuneka yanele isixhobo sokucwangcisa.

7.7.3 Ivalve yokunciphisa uxinzelelo lwe-lock, ngelixa uvala iziphelo ezimbini, jika ivalve yokulawula uxinzelelo de igeyiji yoxinzelelo ibonise uxinzelelo lwe-fusion, olumiselwa zixhobo zombhobho.

7.8 Ukucwangcisa

7.8.1 Yahlula iiclamps ngokusebenza kwivalve yendlela kunye nevalve yokukhulula uxinzelelo evuleke ngokupheleleyo.

7.8.2 Beka isixhobo sokucwangcisa phakathi kweziphelo zemibhobho emibini kunye nokutshintsha, sondela kwiziphelo zemibhobho ngakwisixhobo sokucwangcisa ngokusebenza kwivalve yesalathiso “phambili”, kwaye ulungelelanise ivalve elawula uxinzelelo ukugcina uxinzelelo olufanelekileyo de kuvele ukuchetywa okuqhubekayo kokubini. macala.Qaphela: 1) Ukutyeba kwee-shavings kufuneka kube ngaphakathi kwe-0.2 ~ 0.5mm kwaye kunokutshintshwa ngokulungelelanisa ukuphakama kwesixhobo sokucwangcisa.

I-2) Uxinzelelo lokucwangcisa akufanele ludlule i-2.0 MPa ukuphepha umonakalo wesixhobo sokucwangcisa.

7.8.3 Emva kokucwangciswa, Yahlula iziqhoboshi kwaye ususe isixhobo sokucwangcisa.

7.8.4 Vala iziphelo ezibini ukuze uzilungelelanise. Ukuba ukungahambi kakuhle kudlula i-10% yobunzima bombhobho, yiphucule ngokukhulula okanye ukuqinisa i-clamps ephezulu. Ukuba umsantsa phakathi kweziphelo udlula i-10% yobunzima bodonga lombhobho, ukucwangcisa umbhobho kwakhona de ufumane imfuneko.

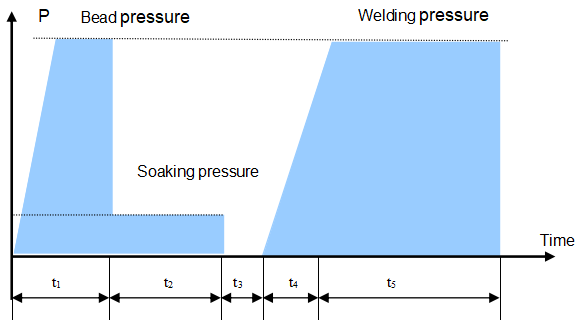

7.9 Ukuwelda

7.9.1 Seta ixesha lokufunxa kunye nexesha lokupholisa ngokwenkqubo ye-welding.

7.9.2 Emva kokususa isixhobo sokucwangcisa, beka ipleyiti yokufudumeza, Tshixa ngokuthe ngcembe ivalve yokukhulula uxinzelelo ngelixa utyhalela phambili ivalve yesalathiso, eyonyusa uxinzelelo lobushushu kuxinzelelo oluchaziweyo lwe-fusion.1) Umbhobho uphela unamathele kwipleyiti yokufudumeza kwaye ukudibanisa kuqala.

7.9.3 Xa iliso elincinane lisakheka, tyhala umva ivelufa ephakathi ukuze ugcine uxinzelelo. Jika ivalve yokujonga ujingi ukuthoba uxinzelelo kuxinzelelo lokumanzisa (P2) kwaye emva koko uyitshixe ngokukhawuleza. Emva koko cofa iqhosha lexesha lokucwina ukuya kwixesha.

7.9.4 Emva kokufunxwa (ii-alam ze-buzzer), vula izithinteli ngokusebenza kwivalve yendlela kwaye ususe ipleyiti yokufudumeza ngokukhawuleza.

7.9.5 Joyina iziphelo ezibini ezinyibilikisiweyo ngokukhawuleza kwaye ugcine ivalve yendlela kwi "forward" ixesha elifutshane kwaye ubuyisele umva kwindawo ephakathi ukugcina uxinzelelo. Ngeli xesha, ukufundwa kwi-gauge yoxinzelelo luxinzelelo lwe-fusion (ukuba akunjalo, lulungise ngokusebenza kwivalve yokulawula uxinzelelo).

7.9.6 Cofa phantsi iqhosha lexesha lokupholisa xa kuqala ukupholisa. Emva kokuba ixesha lokupholisa liphelile, i-alamu ye-buzzer iyakhala. Phinda uhlaziye uxinzelelo lwenkqubo ngokusebenza kwivalve yokukhulula uxinzelelo, vula i-clamps kwaye ususe amalungu.

7.9.7 Qwalasela umdibaniso ngokwemigangatho yenkqubo yokuwelda.

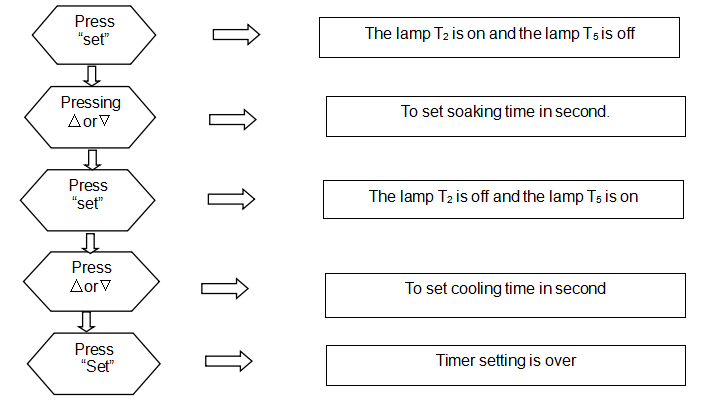

7.10 Isilawuli sobushushu kunye nesibali-xesha

7.10.1 Ukusetha ixesha

7.10 Isilawuli sobushushu kunye nesibali-xesha

7.10.1 Ukusetha ixesha

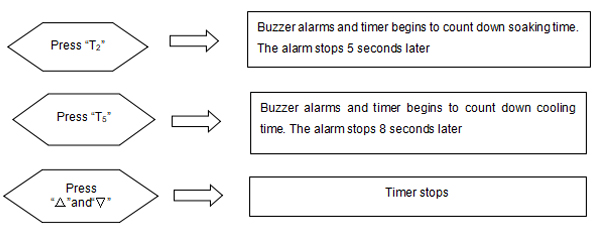

7.10.2 Ukusetyenziswa kwexesha

7.10.3 Ukusetha isilawuli sobushushu

1) Cinezela "SET" ngaphezu kwemizuzwana ye-3 de "sd" iboniswe kwifestile ephezulu

2) Cinezela "∧" okanye "∨" ukutshintsha ixabiso kwiqondo lokushisa elichaziweyo (cofa "∧" okanye "∨" ngokuqhubekayo, ixabiso liya kudibanisa okanye lisuse ngokuzenzekelayo)

3) Emva kokuseta, cofa u-"SET" ukuze ubuyele ekubekeni iliso kunye nokulawula ujongano

iReference Welding Standard (DVS2207-1-1995)

8.1 Ngenxa yomgangatho owahlukileyo we-weldingskunye nezinto zePEs, ixesha kunye noxinzelelo lwesigaba senkqubo ye-fusion yahlukile. Icebisa ukuba iiparamitha zewelding zokwenyani kufuneka zingqinwe ngemibhobho kunye nezixhobo zokwenziwa

8.2Ukunikezelwa kweqondo lokushisa kwi-welding yeepayipi ezenziwe kwi-PE,I-PP kunye ne-PVDF ngokwe-DVS isuka kwi-180℃ ukuya kwi-270℃. Ubushushu besicelo sepleyiti yokufudumeza bungaphakathi kwe-180~230 ℃, kunye nayoMizembe.sUbushushu be-urface bunokufikelela kuma-270 ℃.

8.3Umgangatho weReferensiDVS2207-1-1995

| Ubunzima bodonga (mm) | Ubude be-bead(mm) | Uxinzelelo lokwakha amaso(MPa) | Ixesha lokuhamba t2(Isiqendu) | Uxinzelelo olumanzi(MPa) | Ukutshintsha kwexesha t3(umzuzwana) | Ixesha lokwakha uxinzelelo t4(umzuzwana) | Uxinzelelo lwe-Welding(MPa) | Ixesha lokupholisa t5(imiz) |

| 0~4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45~70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7~12 | 1.5 | 0.15 | 70~120 | ≤0.02 | 6~8 | 6~8 | 0.15±0.01 | 10~16 |

| 12~19 | 2.0 | 0.15 | 120~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16~24 |

| 19~26 | 2.5 | 0.15 | 190~260 | ≤0.02 | 10~12 | 11~14 | 0.15±0.01 | 24~32 |

| 26~37 | 3.0 | 0.15 | 260~370 | ≤0.02 | 12~16 | 14~19 | 0.15±0.01 | 32~45 |

| 37~50 | 3.5 | 0.15 | 370~500 | ≤0.02 | 16~20 | 19~25 | 0.15±0.01 | 45~60 |

| 50~70 | 4.0 | 0.15 | 500~700 | ≤0.02 | 20~25 | 25~35 | 0.15±0.01 | 60~80 |

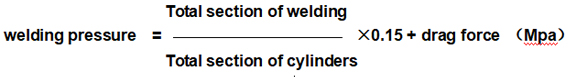

Phawula:Uxinzelelo lwe-bead build-up kunye noxinzelelo lwe-welding kwifom luxinzelelo olucetyiswayo lwe-interface, uxinzelelo lwegeyiji kufuneka lubalwe ngale fomyula ilandelayo.

Inkqubo yokuFaka iFabrication

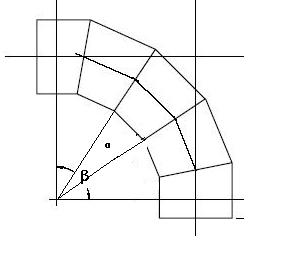

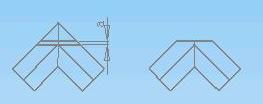

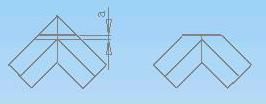

9.1 Ukwenza ingqiniba

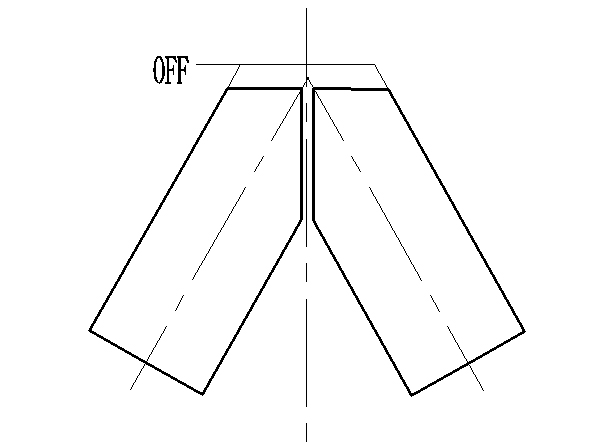

9.1.1 Ngokwe-angle yengqiniba kunye nobuninzi beendawo zokuwelda, i-angle ye-welding phakathi kwenxalenye nganye inokugqitywa.

Ingcaciso: α - i-angle ye-welding

β - i-engile yengqiniba

n - ubungakanani bamacandelo

Umzekelo: i-90 ° i-elbow yahlulwe yangamacandelo amahlanu ukuba i-welding, i-angle ye-welding α=β / (n-1) = 90 ° / (5-1) = 22.5 °

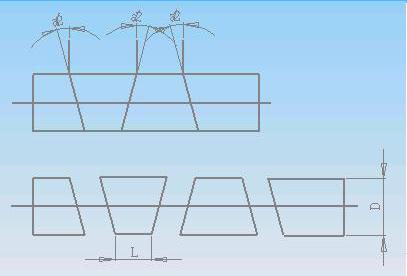

9.1.2 I-min dimension ye-min ye-welding part kwi-welding parts quantities inqunyulwa ngesarha yebhanti ngokweengile.

Ingcaciso:

D - ngaphandle kobubanzi bombhobho

L - Min ubude bayo yonke inxalenye

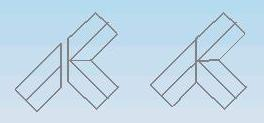

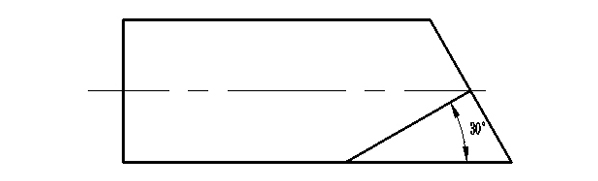

9.2 Inkqubo yokuveliswa kweentsana

9.2.1 Iimathiriyeli zinjengomzobo ulandelayo:

9.2.2 Ukuwelda njengesakhiwo somzobo:

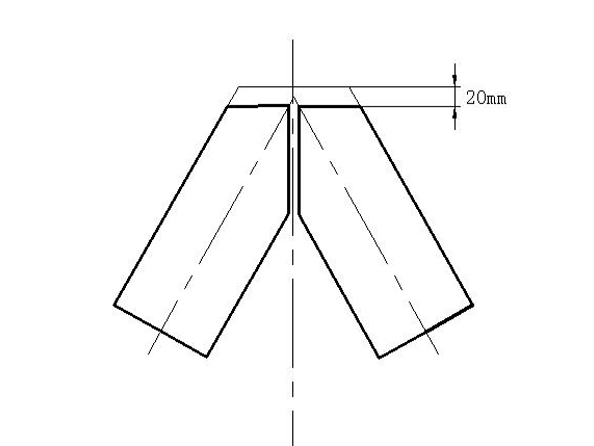

9.2.3 I-engile isikwa njengomzobo

Qaphela: Umlinganiselo “a” akufunekanga ube ngaphantsi kwama-20㎜enjengomda wokucwangcisa kunye nembuyekezo yentsimbi enyibilikayo.

9.2.4 I-Welding njengesakhiwo somzobo, ii tee ziye zaveliswa.

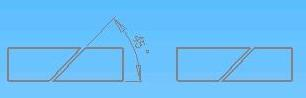

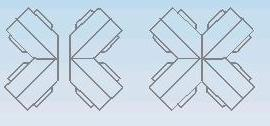

9.3 Inkqubo yokwenza imibhobho enqamlezileyo elinganayo

9.3.1 Iimathiriyeli zisikwa njengalo mzobo ulandelayo

9.3.2 Izibini ezidibanisayo zidityanisiwe njengesakhiwo sedayagram:

9.3.3 I-engile isikwa njengomzobo:

Qaphela: Umlinganiselo “a” akufunekanga ube ngaphantsi kwama-20㎜,Okucwangcisa umda kunye nokuhlawulela intsimbi enyibilikayo.

9.3.4 Idityaniswe njengesakhiwo somzobo.

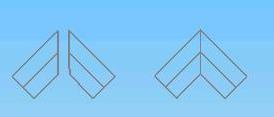

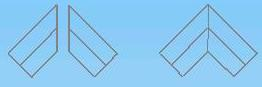

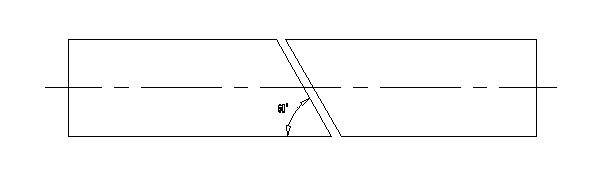

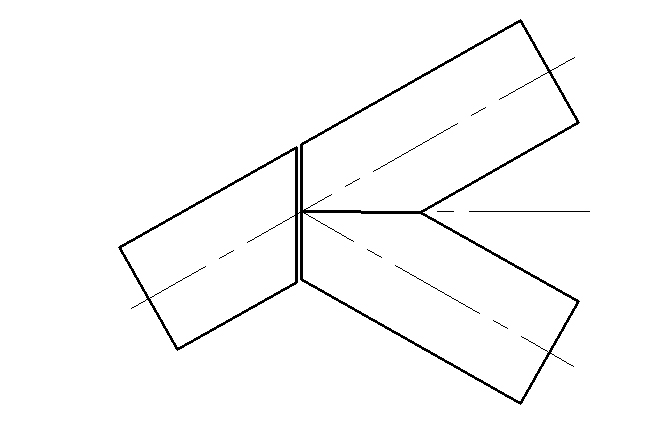

9.4 Inkqubo yokwenziwa kofakelo lwemilo “Y”(45 ° okanye 60 °)

9.4.1 sika ngolu hlobo lulandelayo(thatha ama-60 ° "Y" afakelweyo njengomzekelo)

9.4.2 Qhubekela kwi welding yokuqala njengale mizobo ilandelayo:

9.4.3 Lungisa iiclamps kwaye uqhubekele kwiwelding yesibini.

9.5 ezinye izixhobo zokuwelda

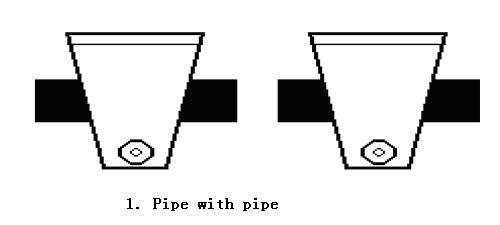

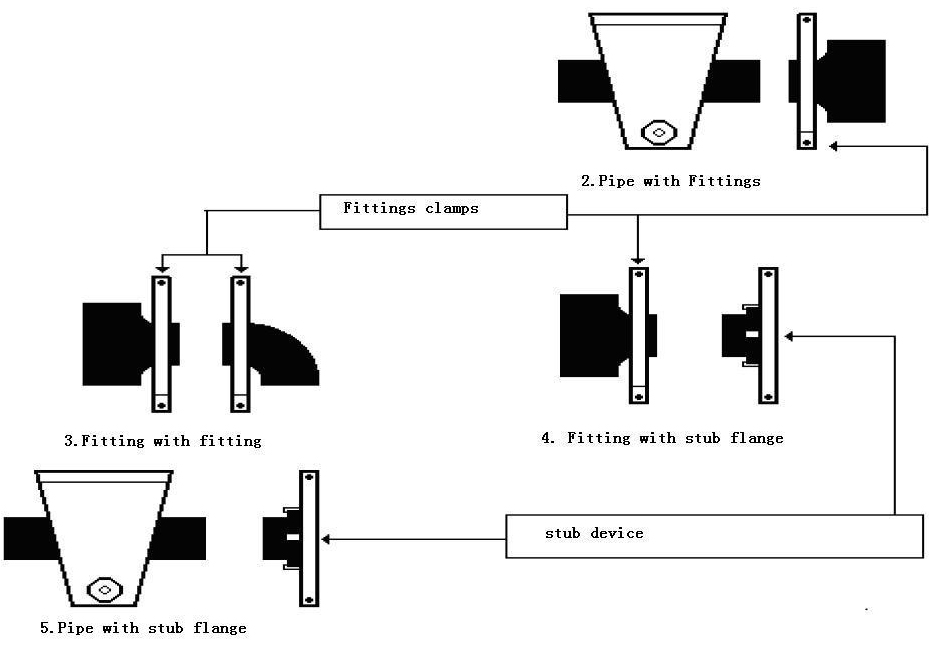

9.5.1. Umbhobho ngombhobho

9.5.2. Umbhobho ngokufakela

9.5.3 Ukufakwa ngokufanelekileyo

9.5.4 Ukufakela i-stub flange

9.5.5 Umbhobho one-stub flange

Ukuhlalutya ukungasebenzi kakuhle kunye nezisombululo

10.1 Ukuhlalutya iingxaki zomgangatho wamalungu rhoqo:

10.2 Ugcino

uIpleyiti yokufudumeza eqatywe nge-PTFE

Nceda uqaphele ukuphatha isipili sokufudumeza ukuze uthintele umonakalo kwi-PTFE yokwambathisa.

Gcina rhoqo ucoce PTFE imiphezulu coated, ukucocakufaneleyenziwe ngomphezulu osafudumeleyo ngokusebenzisa ilaphu elithambileyo okanye iphepha, ukuthintela imathiriyeli erhabaxa oko kunokonakalisa imiphezulu egqunywe yi-PTFE.

Ngamaxesha athile, sicebisa ukuba:

- Coca imiphezulu ngokusebenzisa isicoci esikhawulezayo esiphuma emoyeni (utywala)

- Jonga ukuqiniswa kwezikrufu kunye nentambo kunye nemeko yeplagi

uIsixhobo sokucwangcisa

Kucetyiswa ngamandla ukuba uhlale ucocekile iincakuba kwaye uhlambe iipulleys ngokusebenzisa isefu.

Ngamathuba aqhelekileyo qhuba umsebenzi opheleleyo wokucoca kunye ne-lubrication yangaphakathi

uiyunithi Hydraulic

Iyunithi yolwelo olwenziwa ngamanzi aphantsi ayifuni londolozo lukhethekileyo nangona kunjalo kufuneka ilandelwe le miyalelo ilandelayo:

a. Jonga ngamaxesha athile i-oyile ethe tyaba kwaye ukuba wongeze ngohlobo lweoyile:

I-horizontal akufunekanga ibe ngaphantsi kwe-5 cm ukusuka kwitanki ephezulu ethe tye.

Ukujonga rhoqo ngeentsuku zokusebenza ezili-15 kuyacetyiswa ngamandla.

b. Yitshintshe ngokupheleleyo ioyile rhoqo kwiinyanga ezi-6 okanye emva kweeyure zokusebenza ezingama-630.

c. Gcina iyunithi ye-hydraulic icocekile ngononophelo olulodwa kwitanki kunye nokudibanisa ngokukhawuleza.

10.3 Ukuhlalutya ukungasebenzi rhoqo kunye nesisombululo

Ngexesha lokusetyenziswa, iyunithi ye-hydraulic kunye neeyunithi zombane zinokubonakala iingxaki ezithile. Ukungasebenzi kakuhle kudweliswe ngolu hlobo lulandelayo:

Nceda usebenzise izixhobo ezincanyathiselwe, iinxalenye ezisecaleni okanye ezinye izixhobo ezinesatifikethi sokhuseleko ngelixa ulungisa okanye utshintsha iindawo. Izixhobo kunye neendawo ezisecaleni ngaphandle kwesiqinisekiso sokhuseleko azivumelekanga ukuba zisetyenziswe.

| Ukungasebenzi kakuhle kweyunithi ye-hydraulic | |||||

| No | iinkqubo zininzi | uyahlalutya | izisombululo | ||

| 1 | Injini ayisebenzi |

ikhululiwe

| |||

| 2 | Injini ijikeleza kancinane kakhulu ngengxolo engaqhelekanga |

| ngaphezu kwe-3 MPa

| ||

| 3 | Isilinda sisebenza ngokungaqhelekanga |

itshixiwe ngokuqinileyo

| ukuphuma emoyeni. | ||

| 4 | Ukutsala ipleyiti ehambisa isilinda ayisebenzi |

ivalve ivaliwe |

ivalve yokuphuphuma (i-1.5 MPa ifanelekile).

| ||

| 5 | Ukuvuza kwesilinda | 1. Iringi yeoli iyimpazamo 2. Isilinda okanye ipiston yi yonakele kakhulu | 1. Faka endaweni yeringi yeoli 2. Faka endaweni yesilinda | ||

| 6 | Uxinzelelo alunakunyuswa okanye ukuguquguquka kukhulu kakhulu | 1. Undoqo wevalve yokuphuphuma uvalekile. 2. Impompo iyavuza. 3. I-slack edibeneyo yempompo yi ikhululwe okanye isitshixo segroove siyatyibilika. | 1. Coca okanye ubuyisele undoqo yevalve yokuphuma kwamanzi 2. Faka indawo yempompo yeoli 3. Faka indawo ye-joint slack | ||

| 7 | Uxinzelelo lokusika alukwazi ukulungiswa | 1. Isiphaluka sisiphoso 2. Ikhoyili ye-electromagnetic iyimpazamo 3. Ivalve yokuphuma ivalekile 4. Ivalve yokusika yokuphuphuma ayiqhelekanga | 1. Jonga isekethe (i-diode ebomvu kwikhoyili ye-electromagnetic kukhanya) 2. Faka indawo yekhoyili ye-electromagnetic 3. Coca undoqo wevalve yokuphuma kwamanzi 4. Qwalasela ivalve yokusika | ||

|

Ukungasebenzi kakuhle kweeyunithi zombane | |||||

| 8 | Umatshini wonke awusebenzi |

| 1. Jonga intambo yamandla 2. Jonga amandla okusebenza 3. Vula isiphazamisi sempazamo emhlabeni | ||

| 9 | Iihambo zokutshintsha iimpazamo eziphantsi |

| 1. Jonga iintambo zombane 2. Jonga izinto zombane. 3. Jonga amandla aphezulu isixhobo sokhuseleko | ||

| 10 | Ukunyuka kwamaqondo obushushu ngendlela engaqhelekanga |

4. 4. Ukuba ufundo lwesilawuli seqondo lobushushu lungaphezu kwe-300℃, nto leyo ebonisa ukuba isivamvo soluvo singonakala okanye uqhagamshelo lukhululwe. Ngaba umlawuli weqondo lokushisa kufuneka abonise i-LL, ebonisa ukuba inzwa inesekhethi emfutshane. Ngaba umlawuli weqondo lokushisa ubonise i-HH, ebonisa ukuba isiphaluka senzwa sivuliwe. 5. Lungisa ubushushu ngeqhosha elibekwe kwisilawuli sobushushu.

| abafowunelwa

umlawuli

seta ubushushu

abafowunelwa ukuba kuyimfuneko | ||

| 11 | Ukuphulukana nolawulo xa ufudumeza | Ukukhanya okubomvu kuyakhanya, kodwa iqondo lobushushu lisanyuka, oko kungenxa yokuba isinxibelelanisi sisiphoso okanye amalungu 7 kunye no-8 akakwazi ukuvula xa ufumana ubushushu obufunekayo. | Buyisela isilawuli sobushushu | ||

| 12 | Isixhobo sokucwangcisa asijikelezi | Umda wokutshintsha awusebenzi okanye iindawo zomatshini zesixhobo sokucwangcisa ziyanqunyulwa. | Buyisela umda wesixhobo sokucwangcisa tshintsha okanye i-sprocket encinci | ||

ISekethe kunye neYunithi ye-Hydraulic Diagram

11.1 Umzobo weyunithi yesekethe(ibonwa kwisihlomelo)

11.2 Umzobo weyunithi ye-hydraulic(ibonwa kwisihlomelo)

Itshathi yokuSebenza emajukujukwini