SD200 BUTT FUSION UMACHINE ISIKHOKELO SOKUSEBENZA

Uluhlu olusebenzayo kunye neParameter yobuGcisa

| Uhlobo | SHDS200 |

| Izinto eziphathekayo | PE, PP kunye nePVDF |

| Uluhlu lwedayamitha × ubukhulu | 200mm× 11.76mm |

| Ubushushu be-ambient. | -5℃45℃ |

| Ukunikezwa Amandla | 220V±10%, 60Hz |

| Iyonke yangoku | 12A |

| Amandla onke | 2.0 KW |

| Bandakanya:Iheating plate | 1.2 KW |

| Isixhobo sokucwangcisa | 0.8 KW |

| Max. Ubushushu | <270℃ |

| Umahluko kubushushu bomphezulu wepleyiti yokufudumeza | ± 5℃ |

| Max. uxinzelelo lwefusion | 1040N |

| Ubunzima bubonke (kg) | 35KG |

Inkcazo ekhethekileyo

Ngaphambi kokusebenzisa umatshini, nabani na kufuneka afunde le nkcazo ngononophelo kwaye ayigcine kakuhle ukuqinisekisa ukhuseleko lwesixhobo kunye nokhuseleko lwabanye.

3.1 Lo matshini awunakusetyenziselwa ukuwelda izinto ezingachazwanga; kungenjalo umatshini unokonakala okanye ubangele ingozi.

3.2 Ungawusebenzisi umatshini kwindawo enengozi yokudubula

3.3 Lo matshini kufuneka usebenze ngabasebenzi abanoxanduva, abaqeqeshiweyo nabaqeqeshiweyo.

3.4 Umatshini kufuneka usebenze kwindawo eyomileyo. Amanyathelo okukhusela kufuneka amkelwe xa esetyenziselwa imvula okanye kumhlaba omanzi.

34.5 Amandla egalelo angaphakathi kwe-220V±10%,60 Hz. Ukuba umgca wokufaka owandisiweyo usetyenzisiwe, umgca kufuneka ube necandelo elikhokelayo elaneleyo.

Ukwaziswa koMshini

Umatshiniiqulatheyesakhelo esisisiseko, ipleyiti yokufudumeza, isixhobo sokucwangcisa kunye nenkxaso.

Umyalelo wokusetyenziswa

5.1 Isixhobo sonke kufuneka sibekwe kwinqwelomoya ezinzileyo neyomileyo ukuze isebenze.

5.2 Ngaphambi kokuba usebenze qinisekisa ezi zinto zilandelayo:

Unikezelo lwamandla luchaziwe ngokomatshini wokudityaniswa kweempundu

Intambo yombane ayophukanga okanye iguge

Iincakuba zesixhobo sokucwangcisa zibukhali

Zonke izixhobo ziqhelekile

Zonke iindawo eziyimfuneko kunye nezixhobo ziyafumaneka

Umatshini ukwimeko entle

5.3 Beka izinto ezifakelweyo ezifanelekileyo ngokwedayamitha yangaphandle yombhobho/yokufakela

5.4 Inkqubo yokuwelda

5.4.1. Ngaphambi kwe-welding, okokuqala, khangela ukuba kukho imikrwelo okanye i-fissures ebusweni bemibhobho / izixhobo. Ukuba ubunzulu bemikrwelo okanye i-fissures budlula i-10% yobunzima bodonga, susa imikrwelo okanye i-fissures.

5.4.2 Coca umphezulu wangaphakathi nangaphandle wombhobho odityanisiweyo.

5.4.3 Beka imibhobho/izifakelo kwaye ugcine ubude obude bemibhobho/iziphelo zokufakelwa ukuze zidityaniswe zilingane (ngokufutshane kangangoko kunokwenzeka). Esinye isiphelo sombhobho kufuneka sixhaswe ngama-roller ukunciphisa ukukhuhlana. Qinisa izikrufu zeclamps ukulungisa imibhobho/izifakelo.

5.4.4 Beka isixhobo sokucwangcisa, usitshintshe kwaye uvale imibhobho/iziphelo zofakelo ngokusebenzisa iirodi zomqhubi ezimbini ngokuchasene nesixhobo sokucwangcisa de kuvele ukuchetywa okuqhubekayo kunye ne-homogenous kumacala omabini. Ukwahlula isakhelo, cima isixhobo sokucwangcisa kwaye usisuse. Ubukhulu be-shavings kufuneka bube ngaphakathi kwe-0.2 ~ 0.5 mm kwaye bunokulungiswa ngokulungelelanisa ukuphakama kwezixhobo zokucwangcisa izixhobo.

6.4.5 Vala imibhobho/iziphelo zokufaka kwaye ujonge ulungelelwaniso. Ukungahambi kakuhle akufanele kudlule i-10% yobunzima bodonga, kwaye inokuphuculwa ngokukhulula okanye ukuqinisa i-screws of clamps. Umsantsa phakathi kweziphelo zemibhobho emibini akufanele udlule i-10% yobukhulu bodonga; kungenjalo imibhobho/izifakelo kufuneka zicwangciswe kwakhona.

5.4.6 Sula uthuli kwaye unqumle kwipleyiti yokufudumeza (Musa ukukrwela i-PTFE umaleko kumphezulu wepleyiti yokufudumeza).

5.4.7 Beka ipleyiti yokufudumeza kwifreyimu emva kokuba ifumene ubushushu obufunekayo. Phakamisa uxinzelelo unyuke ufikelele kukhankanywa ngokusebenza kwisiphatho de intsimbi ifikelele kubude obufunekayo.

5.4.8 Nciphisa uxinzelelo kwixabiso elaneleyo ukugcina macala omabini echukumisa ipleyiti yokufudumeza ixesha elichaziweyo.

5.4.9 Xa ixesha liphelile yahlula isakhelo kwaye ususe ipleyiti yokufudumeza, dibanisa amacala amabini ngokukhawuleza.

5.4.10 Yandisa uxinzelelo de kuvele iliso elifunekayo. Xhasa isixhobo sokutshixa ukugcina umdibaniso uphole ngokwawo. Ekugqibeleni vula i-clamps kwaye ukhuphe umbhobho odibeneyo.

5.4.11 Qwalasela ngokubona ijoyini. Umdibaniso kufuneka ube yi-symmetry egudileyo, kwaye i-bottom of groove phakathi kobuhlalu akufanele ibe ngaphantsi kombhobho. Ukungahambi kakuhle kweentsimbi ezimbini akufanele kudlule i-10% yobunzima bodonga, okanye i-welding imbi.

iReference Welding Standard (DVS2207-1-1995)

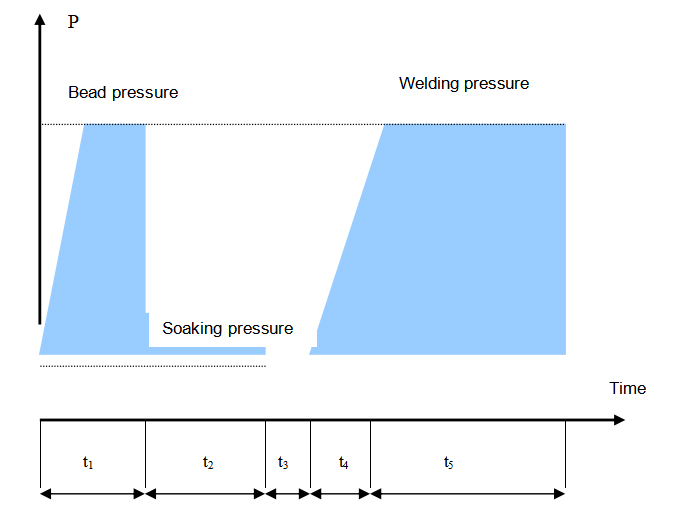

6.1 Ngenxa yokungafani kumgangatho we-welding kunye nezinto ze-PE, ixesha kunye noxinzelelo luyahluka kwizigaba ezahlukeneyo ze-welding. Iphakamisa ukuba iiparameters ze-welding zangempela kufuneka zinikezelwe ngemibhobho kunye nezixhobo'umenzi.

| Ubunzima bodonga (mm) | Ubude bentsimbi (mm) | Uxinzelelo lokwakha amaso (MPa) | Ixesha lokuhamba t2(umzuzwana) | Uxinzelelo lokuntywila (MPa) | Ukutshintsha kwexesha t3(umzuzwana) | Ixesha lokwakha uxinzelelo t4(umzuzwana) | Uxinzelelo lweWelding (MPa) | Ixesha lokupholisa t5(min) |

| 0 ~ 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5~7 | 1.0 | 0.15 | 45 ~ 70 | ≤0.02 | 5~6 | 5~6 | 0.15±0.01 | 6~10 |

| 7 ~12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 ~8 | 6 ~8 | 0.15±0.01 | 10~16 |

| 12 ~ 19 | 2.0 | 0.15 | 120 ~190 | ≤0.02 | 8~10 | 8~11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10~12 | 11 ~ 14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12 - 16 | 14 ~ 19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16 ~ 20 | 19 ~ 25 | 0.15±0.01 | 45 ~ 60 |

| 50 ~ 70 | 4.0 | 0.15 | 500 ~700 | ≤0.02 | 20 ~ 25 | 25 ~ 35 | 0.15±0.01 | 60 ~ 80 |

Phawula:Uxinzelelo lwe-bead build-up kunye noxinzelelo lwe-welding kwifom luxinzelelo olucetyiswayo lwe-interface, uxinzelelo lwegeyiji kufuneka lubalwe ngale fomyula ilandelayo.

Amabinzana:

Uxinzelelo lwe-Welding(Mpa)=(Icandelo lombhobho welding ×0.15N/mm2)/(2 ×8×8×3.14) + Tsala uxinzelelo

Apha, 1Mpa=1N/mm2